- Overview

- Description

- Mods and Accessories

- Stock List

- Custom Designs

Watt-Flex Split Sheath Cartridge Heaters by Hampton Controls

From the Leader in Cartridge Heater Technology

A Unique Split-Sheath Design

That Reduces the Cost of Process Heating

The Revolutionary Watt-Flex Split-Sheath Cartridge Heater

Watt-Flex cartridge heaters last up to 5 times longer than conventional heaters with less downtime for heater replacements and lower maintenance costs. Watt-Flex heaters contract when de-energized, eliminating bore seizure and the need for expensive drill-outs.

Watt-Flex Cartridge Heaters run more efficiently, use less power and last up to 5 times longer than conventional cartridge heaters.

- Maximizes Heat Transfer

- Reduces Maintenance Costs

- Reduces the Cost of Process Heating

Through the patented split-sheath design and highly specialized manufacturing techniques, Hampton Controls Watt-Flex cartridge heaters reduce your total cost of process heating by an average of 40% over other heaters.

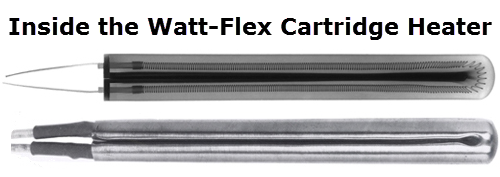

The Watt-Flex heater construction eliminates ceramic cores typically found in conventional cartridge heaters. Hampton Controls has developed and highly-specialized manufacturing techniques to compact high-grade MgO dielectric to its near theoretical maximum around the heater coil, which increases dielectric strength and heat transfer away from the coil which results in significantly longer heater life

Hampton Controls Watt-Flex Cartridge Heaters use a unique, patented split-sheath design that expand when energized to maximize heat transfer through greater contact with the wall of the bore. Better heat transfer means less power is consumed to maintain the set point temperature, reducing operating costs.

- Last 5X Longer

- Higher Watt DENSITY & Temps

- Uniform Temps

- Maximize Heat Transfer

- Use in OVERSIZED Bores

- Ease of Removability

- Hot and Cool Options

- External Thermocouples

Watt-Flex Split Sheath Cartridge Heaters Last 5 Times Longer

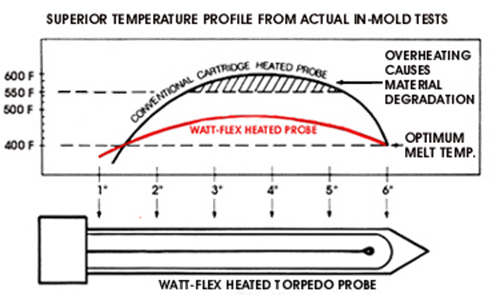

Cartridge heater life is directly related to its internal operating temperature. Watt-Flex cartridge heaters run substantially cooler and have a more uniform temperature profile than conventional heaters.

The result is Watt-Flex heaters that last up to 5 times longer, have less downtime and lower operating costs than conventional cartridge heaters.

Efficient Heat Transfer of Watt Flex Cartridge Heaters

- The high purity MgO dielectric in Watt-Flex heaters is compacted to extreme density, ensuring maximum heat transfer away from the core to the heater sheath.

- As the energized split-sheath expands, it creates intimate contact with the bore wall, efficiently transferring heater sheath to the host metal.

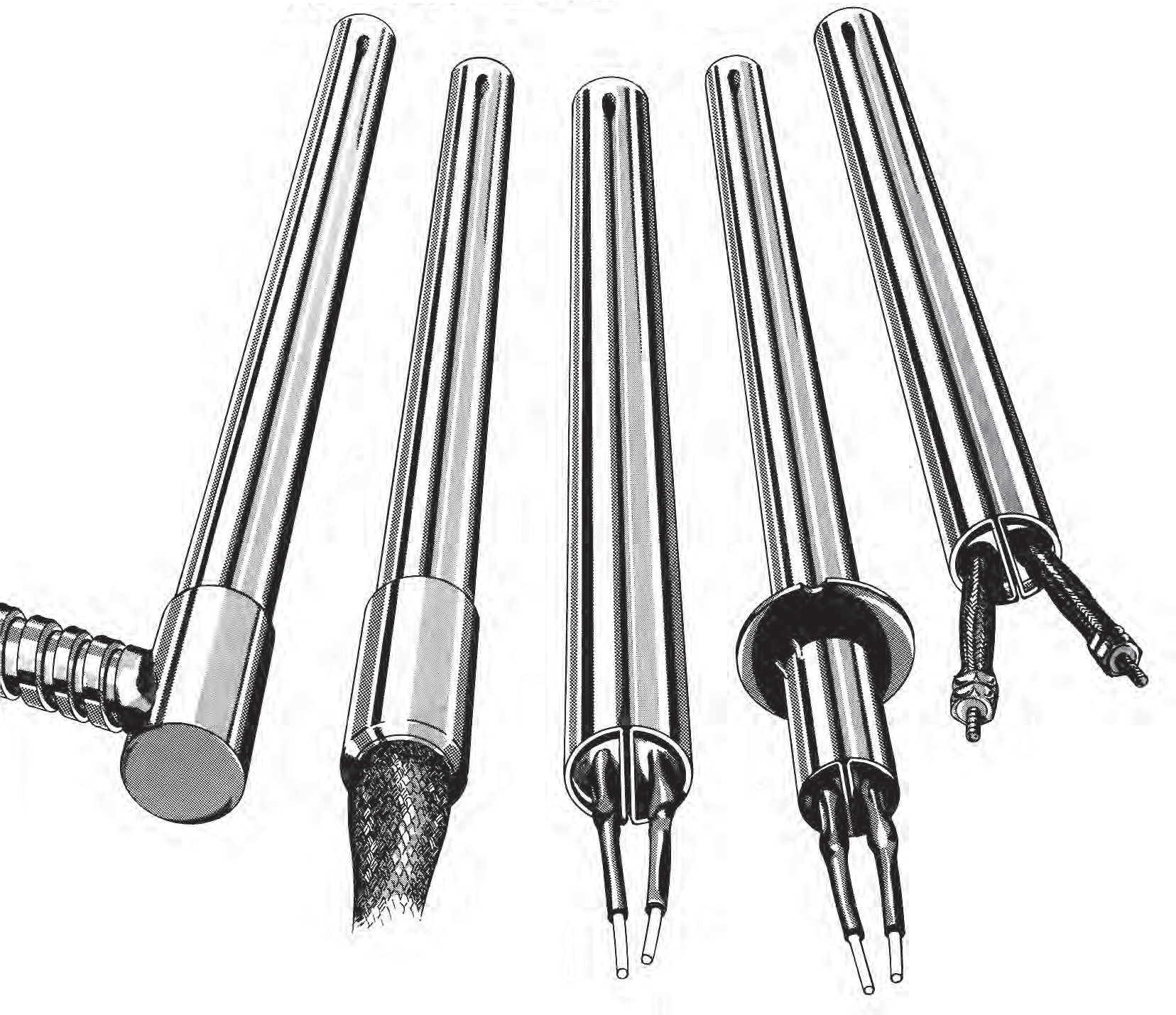

WARNING: Conventional ceramic core cartridge heaters (shown below) use multiple heating cores that can independently burn out, causing a cold section on the sheath. And voids of coil at core junctions produce cold sections on the heater profile.

Conventional Cartridge Heaters Burn OUT

Unlike conventional ceramic heaters, Watt-Flex heaters use a continuous heating coil to achieve a more uniform temperature profile. With Watt-Flex Cartridge Heaters, there are no independent heating element sections to burn out. Watt-Flex Cartridge Heaters are either totally on or totally off.

Watt-Flex Cartridge Heater Last 5 Times Longer

Higher Watt Density and Temperatures

Watt-Flex Cartridge Heater produce up to 50% higher warrant-able watt-densities than conventional heaters and can operate at much higher temperatures -

up to

1900 deg F (1030 deg C ).

The Watt-Flex Cartridge Heater is a high-quality tubular heating element bent back on itself and swaged into a cylindrical format. Hampton Controls manufactures heaters using only high-purity magnesium oxide, nickel chromium resistance wire and stainless steel terminals.

Special filling methods and equipment compact the magnesium oxide inside and around the resistor coil to extreme density. Swaging further compacts the magnesium oxide to virtually maximum density, which yields high dielectric strength and efficient internal heat conduction. Unlike conventional heaters, Watt-Flex cartridge heaters have no ceramic core that can crack during swaging.

Watt-Flex Cartridge Heaters run more efficiently, use less power, last longer and are much simpler and faster to replace than conventional cartridge heaters.

Watt-Flex Cartridge Heater Temperature Profiles

Unlike conventional cartridge heaters, Watt-Flex Cartridge Heater use a continuous heating coil that allows for a more uniform temperature profile.

By varying the watt-density, Watt-Flex heaters can also be configured for customized temperature profiles with varying zones of heat along the heater.

Uniform Temperature Profile from Watt-Flex Cartridge Heaters

Uniform sheath temperature is vital when molding heat-sensitive plastics where the temperature window between gate freeze-off and material degradation is very narrow. The test results below highlight the superior temperature profile along the length of a torpedo probe heated by a Watt-Flex Cartridge Heater.

Customized Temperature Profile

By varying the watt-density, the temperature profile may be custom matched to your specific requirements.

For example, certain applications such as those requiring temperatures higher at the tip of a molding probe than along the sheath can be accomplished with Watt-Flex Cartridge Heater, but not with conventional cartridge heaters. The watt density can be varied to compensate for process heat loss."

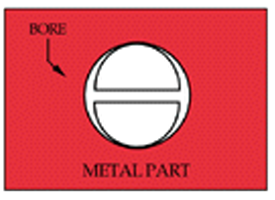

Maximize Heat Transfer of the Watt-Flex Cartridge Heater

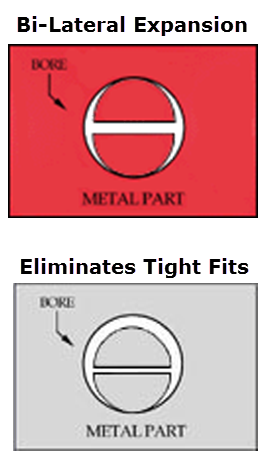

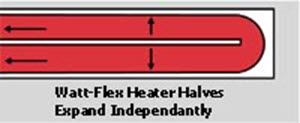

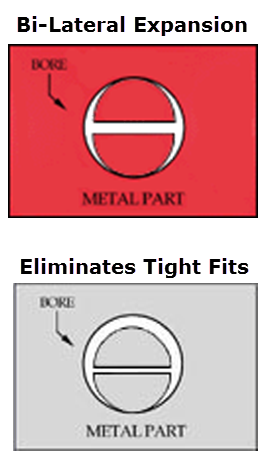

The unique split-sheath design of the Watt-Flex Cartridge Heater allows the independent, bilateral expansion of each half of the heater outward against the walls of the surrounding bore.

The result is greatly improved heat transfer under normal fit conditions of .005" to .007", assuring superior heat transfer, more uniform process heat, greater efficiency, and reduced consumption of electricity. If bores are oversized from previous use and drill-outs, the bilateral sheath expansion will maximize heater-to-bore contact for the most efficient conduction heating.

Comparison of Heat Transfer

Un-even Heat Transfer

Conventional Cartridge Heater

Limited to ordinary thermal expansion, cannot compensate for over-sized bores.

Maximized Heat Transfer

Watt-Flex Heater Energized

The unique bi-lateral expansion of an energized Watt-Flex cartridge heater produces superior metal-to-metal contact with the surrounding bore, thereby maximizing heat transfer.

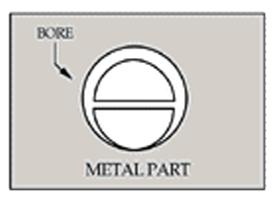

Cooled Metal Part

Watt-Flex Heater De-energized

When de-energized, the Watt-Flex heater contracts for easy removal from bore.

Watt-Flex Split Sheath Cartridge Heaters

Ideal for

Use in Oversized Bores

The unique bi-lateral expansion of Watt-Flex cartridge heaters eliminates the need for tight fits and makes them well-suited for use in over-sized bores where conventional cartridge heaters cannot be used effectively.

Cartridge heater fit is measured as the difference between the inside diameter (I.D.) of the bore and the outside dimension (O.D.) of the heater.

The suggested fit for a Watt-Flex Cartridge Heater is .007" greater than the nominal Watt-Flex heater sheath diameter.

For example, the ideal bore diameter for a 1/2" diameter Watt-Flex heater would be 0.502 --> 0.505". At the maximum tolerance dimension of heater and the minimum bore diameter, the heater would have a 0.005" fit, allowing ease of insertion and removal.

Generally, smaller diameter heaters benefit from a tighter fit and fit can be loosened for larger diameters.

Watt-Flex Cartridge Heaters Eliminate Bore Seizure

The patented split-sheath design of the Watt-Flex cartridge heater reduces your heater change-out costs by preventing heater bore seizure.

Hampton Controls will replace, free of charge, any Watt-Flex Heater that cannot be withdrawn from the bore.

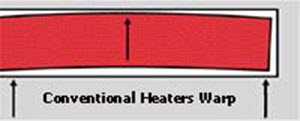

What causes conventional heaters to warp and bind?

In conventional cylindrical heaters, temperature can vary from one side of the heater diameter to the other. These differentials are caused by heat deflection within a close fitting bore, and are the most frequent cause of heater warping and binding during removal.

How the Watt-Flex Split-Sheath prevents bore seizure:

With the Watt-Flex heaters' unique split-sheath design, each half of the heater expands and contracts independently.

When energized, the heater expands to make intimate contact with the bore wall. When de-energized the sheath contracts for ease of removal:

Hampton Controls standard warranty covers the removal of Watt-Flex Heaters from bores, provided that the bore fit is a minimum of 0.005" and there is no bore contamination to cause seizure.

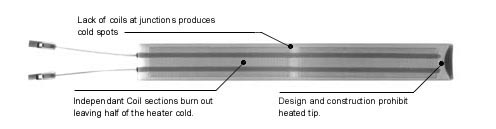

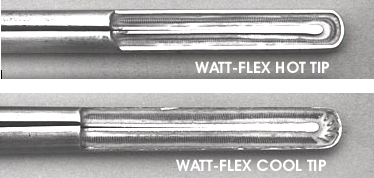

Watt-Flex Heaters - Hot Tip or Cool Tip Options

Watt-Flex Cartridge Heaters use a continuous coil construction that can be designed to deliver either full or reduced power at the tip to suit your process heating application.

Used in injection molding heat probes, for example, the Watt-Flex Hot Tip option can minimize undesirable gate freeze-off.

Conventional heater designs prohibit heated tips.

Watt-Flex Cartridge Heater Designs can Cool and Heat

Watt-Flex Cartridge Heater, however, can be constructed for hot or cool tips by either concentrating or stretching the continuous coil inside the densely compacted MgO dielectric.

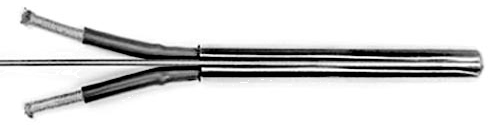

External Thermocouples

Exclusive Watt-Flex Split Sheath Cartridge Heaters Option

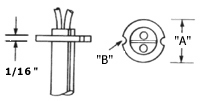

Watt-Flex split-sheath cartridge heaters can be manufactured with a groove along the exterior of the cartridge to accommodate a needle-type thermocouple for more accurate temperature sensing and control.

Watt-Flex external thermocouples out perform internal monitors used in conventional heaters. With Watt-Flex Cartridge Heater, you can:

- Measure temperature at the precise point of heat transfer. Unlike conventional heaters with internal thermocouples that measure internal heater coil temperature, Watt-Flex external thermocouples measure more precisely at the point where heat transfers from the heater to the host metal.

- Monitor temperature at any point along the heater. Hampton Controls Watt-Flex heaters give you the flexibility to monitor heat at any point along the heater, instead of at pre-defined fixed points with internal monitors in conventional heaters.

- Replace heater or thermocouple independently.

With Watt-Flex external thermocouples, you can replace either the heater or the thermocouple independently, without having to replace an operational component as with conventional heater designs.

Thermocouple Specifications

Maximum lengths:

- 15" maximum for grooved heaters with 1/4" or 3/8" diameter heaters.

- 7" maximum for grooved heaters with 1/2" diameter heaters.

Longer heaters using 1/2" diameter or larger heaters, can be center- grooved between the legs to any depth between 6" to 15".

Thermocouples:

- Type J with 48" leads.

- Type K with 48" leads.

Needle diameters:

- 0.040" for 1/4" diameter heaters and all center grooves.

- 0.062" for side-grooved 3/8" and 1/2" diameter heaters.

Watt-Flex Cartridge Heater Modifications and Accessories

Watt-Flex cartridge heaters are built-to-order to meet your electric process heating application. A variety of heater modifications and accessories are available for:

- Abrasion Protection

- Lead Modifications

- Contaminant Protection

- Heater Mounting Accessories

- High Temperature Modifications

- Distributed Wattage

Do YOU need to Design a challenging new heating application? We can help!

With over 20 years of experience in the manufacture of cartridge heaters, Hampton Controls has the engineering expertise and production capabilities to design and produce modified, special, or custom heaters for your most challenging requirements.

Watt-Flex Cartridge Heater Modifications and Accessories

- Abrasion Protection

- Lead Modifications

- Contaminant Protection

- Mounting Accessories

- High Temperature Mods

- Distributed Wattage

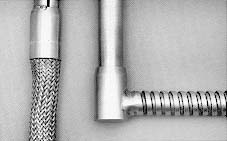

Abrasion Protection

Watt-Flex headers shield lead wires and insulators from abrasion damage caused by machine cycling, severe environment and rough handling.

High-quality stainless steel construction provides long-lasting protection even in the most rugged industrial environments.

Straight and Right Angle Headers

Straight and Right Angle Headers

Watt-Flex | Header O.D. | Hose O.D. |

|---|---|---|

1/4" | 3/8" | 11/32" |

3/8" | 1/2" | 11/32" * |

1/2" | 5/8" | 1/2" |

5/8" | 3/4" | 1/2" |

3/4" | 7/8" | 1/2" |

1" | 1 1/8" | 5/8" |

(* 3/8" diameter right angle header with high-temperature leads has 1/2" hose O.D.) | ||

Stainless Steel Braid - flexible, with tighter bend radius plus the strength of braided strands of high-quality stainless steel.

Stainless Steel BX - interlocking hose provides greater strength and abrasion protection than braid, and a slight economic advantage.

Lead Modifications

Standard Temperature Leads - TGGT insulation (teflon tape primary, glass servings, woven glass braid, teflon coated) over stranded Grade "A" nickel wire. (< 480o F / 250o C).

Standard Temperature Teflon Leads - Extruded PFA over stranded Grade "A" nickel wire.

(< 480o F / 250o C)

High Temperature Leads - Fiberglass insulation (threaded glass servings primary, treated glass braid) over stranded Grade "A" nickel wire. (< 840o F / 450o C).

Fiberglass or Rubber Sleeving - Rubber sleeving provides excellent insulation value for low temperature process heating applications (< 450o F / 230o C). Fiberglass woven glass strands provide good insulation for use in high temperature process heating applications.

Quick Disconnect - a modular plug or terminal junction in the wire for ease of heater disconnection.

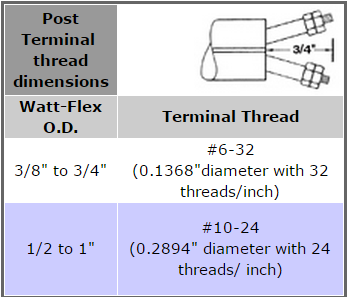

Threaded post terminals - useful when wire must be occasionally disconnected and/or replaced. Often used in conjunction with a bussbar.

Integral Ground Wire - attached to the heater, meant for termination to ground on the machine.

Extra Length Leads - available in any length. For wires longer than 10 feet (3 meters), a quick connect or male/female connector plug assembly can be used to reduce heater cost.

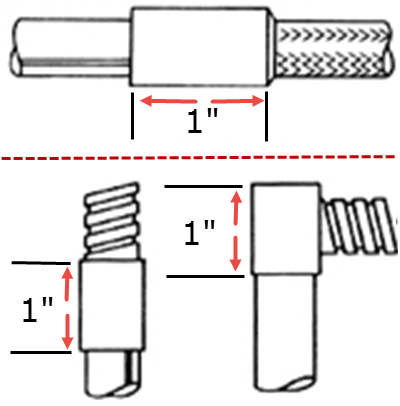

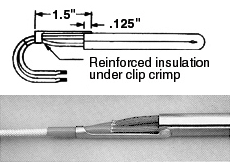

Stainless Steel Clip Support

Stainless Steel Clip Support - displaces and reinforces the point of wire flexure away from the heater terminal connection.

Useful for applications where there is repeated flexing (packaging and sealing).

Contaminant Protection

A protective contaminant barrier inserted into the terminal cavity can protect the cartridge heating element from moisture, dirt and other contaminants that can damage the heating element.

RTV Potting - RTV (Room Temperature Vulcanized) rubber provides an excellent moisture barrier for low temperature process heating applications (< 450o F / 230o C ).

Ceramic Potting - provides good contaminant protection, but is not a complete moisture barrier. Ceramic material supports very high temperature process heating and is rated to

2000+ oF / 1090 oC.

Mounting Modifications

Hampton Controls heating engineers can develop mounting apparatus for any heating application. A sampling of standard accessories are listed below.

- Stainless Steel Flange

- Puller End Plug

- Mounting Bracket

- NPT Fitting

- In Line Diodes

- Threaded Extraction Collars

- Solid Pin Connectors

- Ground Wire

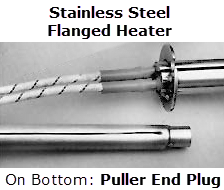

Stainless Steel Flange - available in sizes shown below, the stainless steel flange acts as a mechanical stop at the edge of the heater well.

Puller End Plug - used for heater extraction in applications where the terminal end of the heater is not accessible. Interior thread attaches the puller plug to the heater tip.

Mounting Bracket - an "L" shaped bracket welded to the sheath to act as an insertion stop or for mechanically securing the heater at the edge of the heat sink.

NPT Fitting - used with Watt-Flex replaceable immersion heaters for heating liquids in vats or tanks.

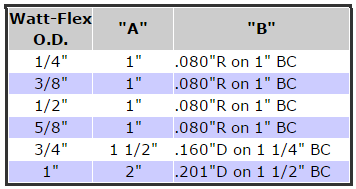

Stainless Steel Flange Dimensions

High Temperature Modifications

- Extra Cold Section at End

- Ceramic Beads

Extra Cold Section at End - when the heater extends out of the bore (through insulation, for example) an extra cold section added to the cartridge heater ensures that the heated section is fully enclosed by the heat sink.

The cold terminal end is usually produced by adding a longer terminal pin so no heat is produced. Longer cold sections are created by stretching the continuous coil resistance wire to limited heat production.

Ceramic Bead Insulation -- Placed over insulated lead wire to protect beyond temperature rating of insulation. Withstands temperatures to 2000° F / 1090 °C.

Distributed Wattage

Watt-Flex Cartridge Heater can be designed with zones of varying watt density, allowing you to put a specific amount of heat exactly where you need it.

Distribution of Watt Density for the Watt-Flex Cartridge Heater

Distributed wattage is ideal for applications where higher temperatures are required at certain points to offset radiant heat loss such as at the ends of a sealing bar or at the tip of the molding probe.

Watt-Flex® Cartridge Heater Standard Dimensions

All Watt-Flex cartridge heaters are built-to-order to match your heating and size requirements. Available sizes for cartridges are listed below.

Watt-Flex heaters eliminate the need for a tight fit. When selecting the right diameter for the bore in your application, keep in mind that the recommended fit for a Watt-Flex diameter is .007" larger than the nominal diameters shown.

For custom sizes and special heating applications, click on the Custom Design Tab above or Contact Hampton Controls for more info: 724-861-0150

We have designed and built high-watt heaters for use across a wide variety of industries and process heating applications such as molds and dies, plastics, package sealing, and liquids in automotive, plastics, composites, aerospace, food service, and more.

Standard Dimensions for Watt-Flex Cartridge Heater

Available Diameters | Nominal Diameters (1) | Standard Cold Section at Terminal End | Minimum - Maximum (2) Lengths |

|---|---|---|---|

1/4" | 0.245" | 5/16" | 1" - 22" |

3/8" | 0.370" | 3/8" | 1 1/2" - 36" |

1/2" | 0.495” | 5/8" | 2" - 50" |

5/8" | 0.620" | 5/8" | 2 1/2" - 72" |

11/16" | 0.683" | 5/8" | 3 1/2" - 64" |

3/4" | 0.745" | 5/8" | 3 1/2" - 90" |

1" | 0.9925" | 1" | 10" - 60" |

| |||

8.0 mm | 7.875 mm | 8.000 mm | 38 - 660 mm |

10.0 mm | 9.875 mm | 9.500 mm | 38 - 915 mm |

12.0 mm | 11.875 mm | 15.875 mm | 50 - 1140 mm |

12.5 mm | 12.375 mm | 15.875 mm | 50 - 1140 mm |

15.0 mm | 14.875 mm | 15.875 mm | 65 - 1250 mm |

16.0 mm | 15.875 mm | 15.875 mm | 65 - 1525 mm |

20.0 mm | 19.875 mm | 15.875 mm | 100 - 1825 mm |

25.0 mm | 24.87 mm | 24.5 mm | 200- 1525 mm |

(1) Tolerances: ± .002" ( 1/4" to 3/4"); ± .0025 (1"); ± .05mm (8mm-20mm) (2) Tolerances: ± 3% with 3/32" minimum; ± 2% above 20" (500 mm) | |||

Order Your Watt-Flex Split Sheath Cartridge Heaters

Hampton Controls looks forward to serving you and supplying you with your Industrial Needs.

Please fill out the information below and it is important to NOTE: Some fields are required.

Feel free to call us if you need any assistance at: 724-861-0150

See our Large Supply by Clicking on the Stock List Tab above or Configure your Watt-Flex Heaters here.

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.