- Overview

- Description

- Clamping

Options

- Terminations

Options

- Stock List

Custom Designs

Ceramic Band Heaters by Hampton Controls

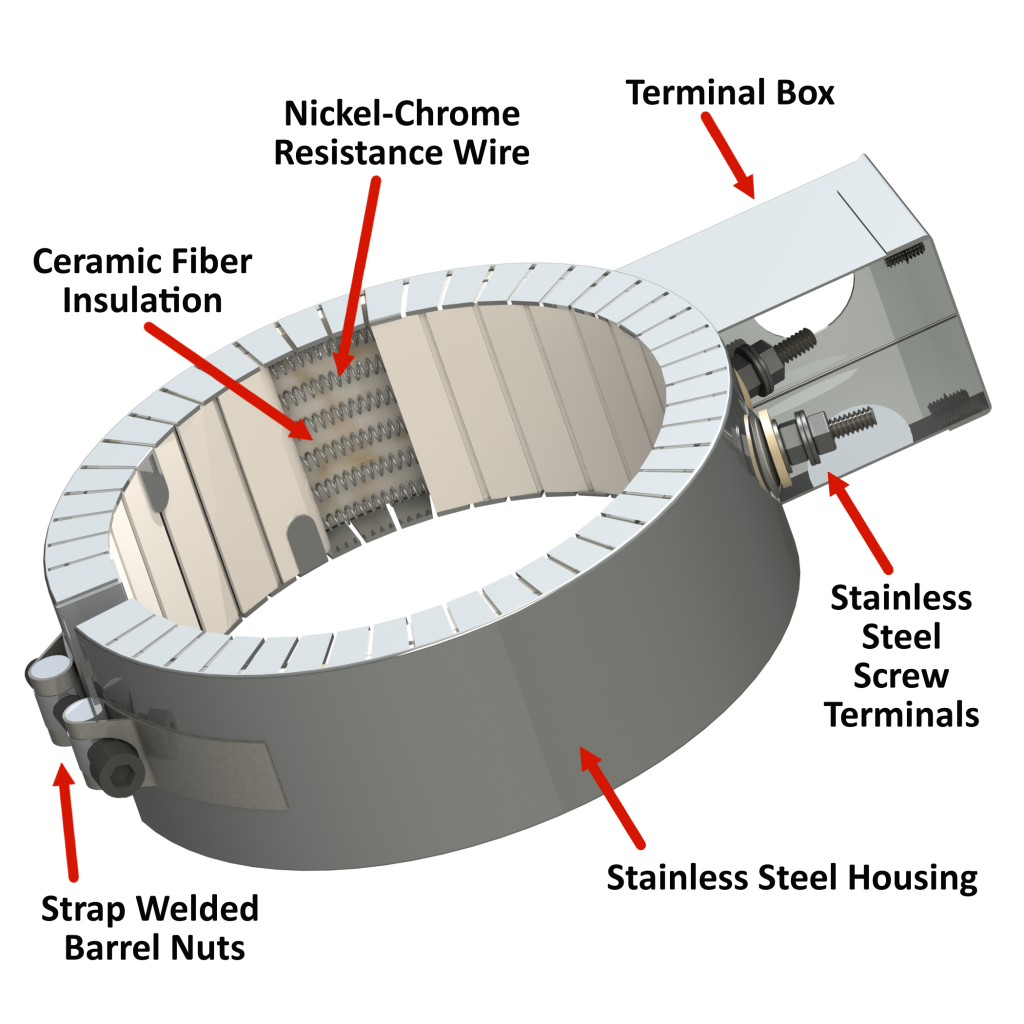

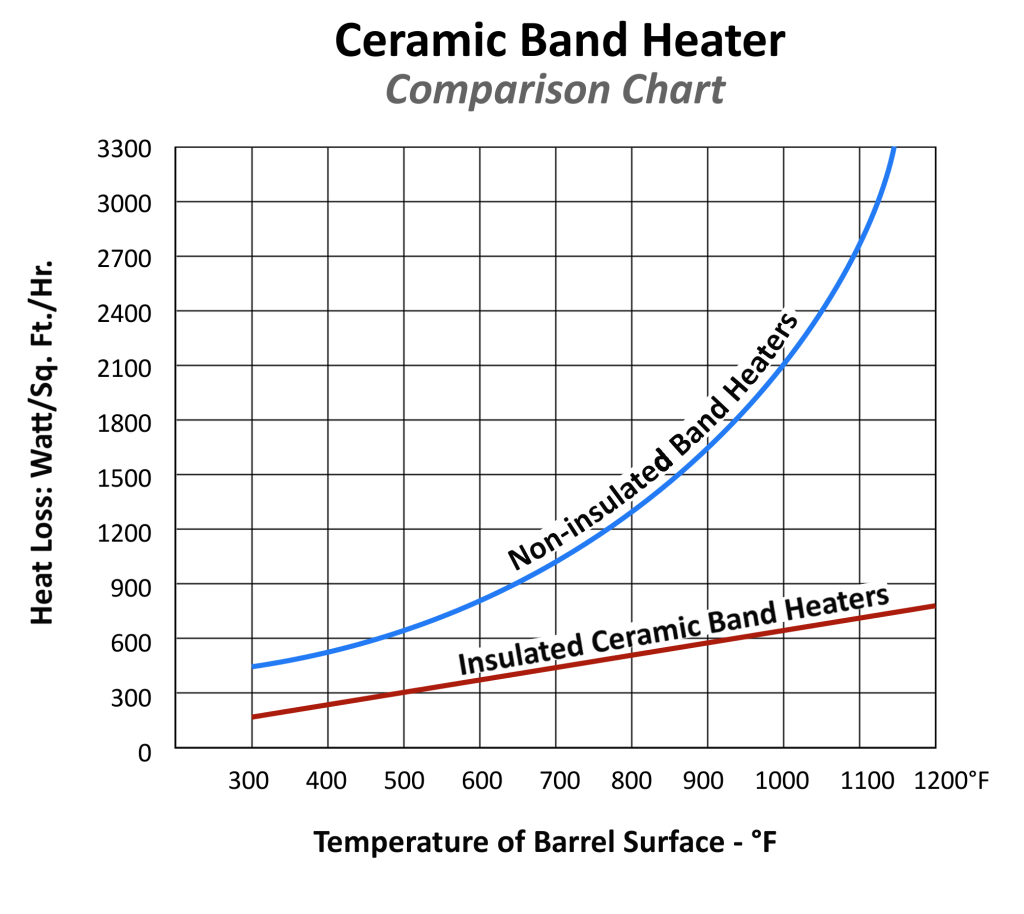

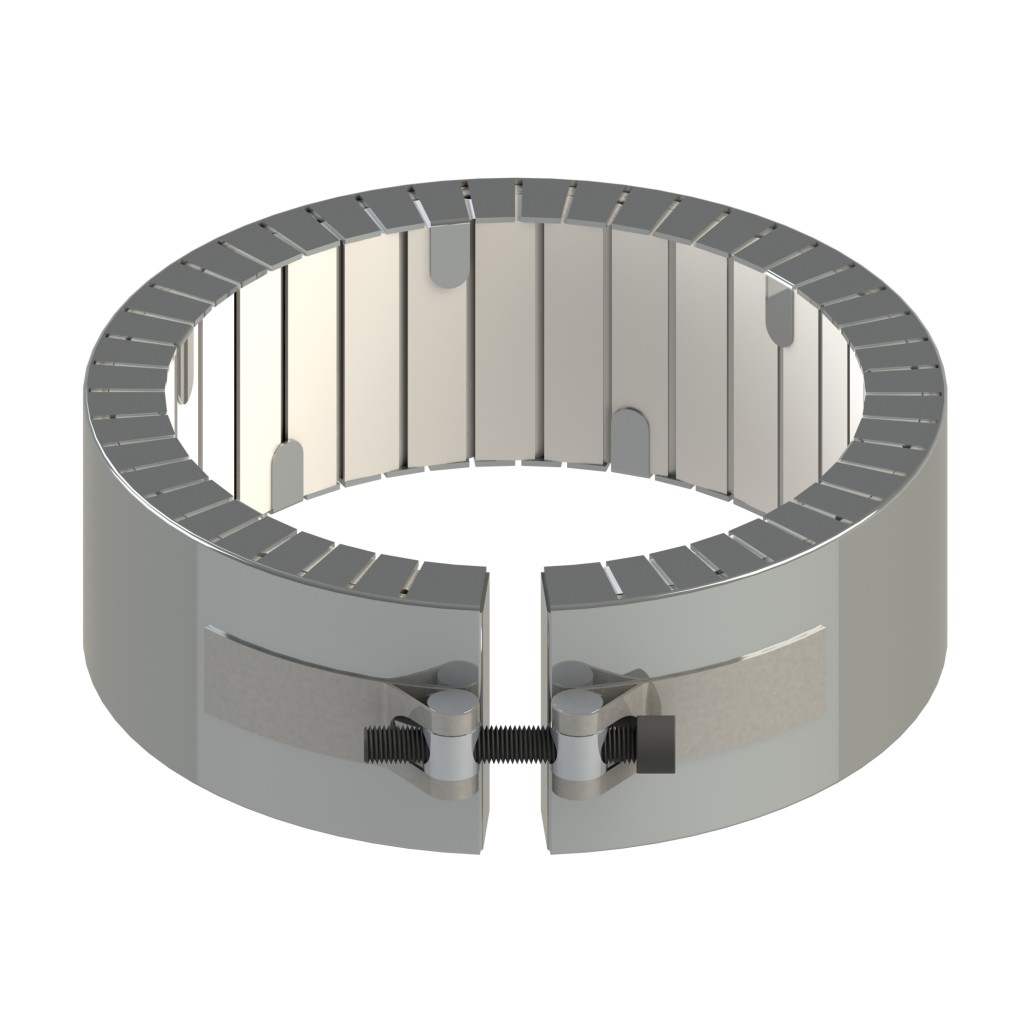

Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic “tiles”. The ceramic core, or “mat” of tiles is housed beneath a stainless steel sheet with serrated edges.

The notched edges fold over to secure the ends and a protective inner liner (to be removed at installation) secures the placement of the tiles.

This combined assembly of the Ceramic Band Heater offers a flexible heating system that yields efficient transmission of conduction and radiated heat. The heat of the Ceramic Band originates from the inner coils that conduct heat at maximum temperatures.

The heated coils evenly deliver heat through the ceramic tiles which radiate energy to the barrel. We offer a variety of Ceramic Band styles from standard to custom configurations.

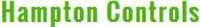

When selecting a ceramic heater, select a heater that best matches the wattage requirements – to decrease the frequency of cycling and temperature overshooting and thereby increase the life of the heater.

When installing a ceramic band heater to replace a non-insulated heater, decrease the total operating wattage by approx. 15-20 percent.

Hampton Controls makes Ceramic Band Heaters for many Applications

The use of Ceramic Band Heaters inserts to support high-temperature nickel-chrome resistance wire allows the Hampton Controls ceramic heater band to operate at temperatures reaching 1,500 degrees Fahrenheit.

Corrosion-resistant metal is slit along the edges to allow easy fitting of the shroud to the object to be heated. The radiant heating effect of ceramic heaters allows construction in widths greater than those in other types of heaters. Wider bands allow fewer heaters per zone and more uniform heat patterns

Features | Applications |

|---|

- FLEXIBLE

- METRIC SIZES

- THERMAL INSULATIONSHROUD

- 1500°F. OPERATING TEMPERATURES

- CORROSION RESISTANT ALLOY SHROUD

| - UNIFORM HEATING PATTERN

- RADIANT HEATING PRINCIPLE

- ENERGY EFFICIENT, 25% SAVINGS

- NICKEL-CHROME RESISTANCE WIRES

| [thrive_custom_box title=” style=’dark’ type=’color’ color=’#dee8ef’ border=’#1e73be’]

DIE HEADS

BLOWN FILM DIES

CHEMICAL REACTORS

EXTRUDER EQUIPMENT

INJECTION MOLDING EQUIPMENT[/thrive_custom_box] |

AVAILABLE IN SPECIAL CONFIGURATIONS | Other Cylinder Heating Applications also. |

[thrive_custom_box title=’Ceremic Band Advantages’ style=’dark’ type=’color’ color=’#dee8ef’ border=’#1e73be’]

- Built in insulation minimizes unwanted change in temperature along the barrel.

- Efficient heat transfer: Heat transfers through radiation, conduction, and convection, so a perfect fit is not required compared to other band heaters.

- Heat transfers are not affected by irregular surfaces or a loose fit.

- Because they operate at higher watt densities, they can be used in wider increments.

- The number of bands used can be reduced with simplified wiring.

- The heater is safer with the cooler external surface – over other band heaters.

- The flexible design allows easy install and removal.[/thrive_custom_box]

Calculating Safe Maximum Wattage for Your Ceramic Heater: |

|---|

Max Watt Density: 45 W/in² Max Temperature: 1300°F (760°C) Max Voltage: 480 VAC per termination Max Amperage per circuit: Lead Wire Termination – 10amp Screw Termination – 25 amp Tolerance: |

|---|

Resistance: +10%, -5% Wattage: -10%, +5% Material: |

|---|

Ceramic tile thickness: 9 mm, and 11.6 mm Coil: Nichrom A® also call Ceramic Fiber Insulation: ¼” thick 430 Stainless Steel heath (housing) |

|

|

[thrive_custom_box title=’Physical Limitations of Ceramic Band Heater Variations’ style=’dark’ type=’color’ color=’#dee8ef’ border=’#1e73be’]

Standard Material: Sheath- is Stainless Steel; Insulation – Ceramic Fiber

Overall Thickness: Insulation is 1/2″ and 5/8″

Standard Width Increments: 1/2″ and Minimum Width: 1″

Minimum Diameter: (Contact the manufacturer if your required size is not listed.)

One Piece: 21″ Two Piece: 44″ Standard Gap: 3/8″

[/thrive_custom_box]

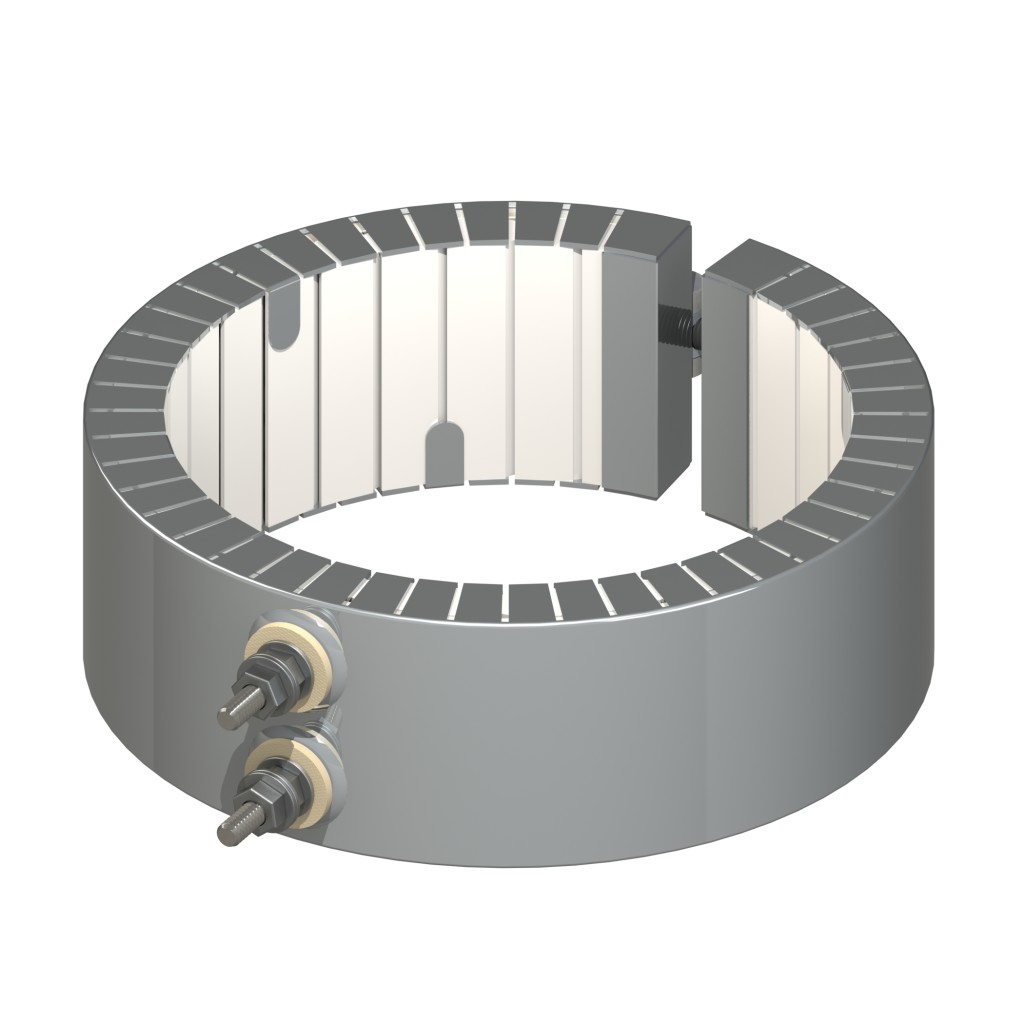

Hampton Controls provides several clamping variations for our Ceramic Band Heaters.

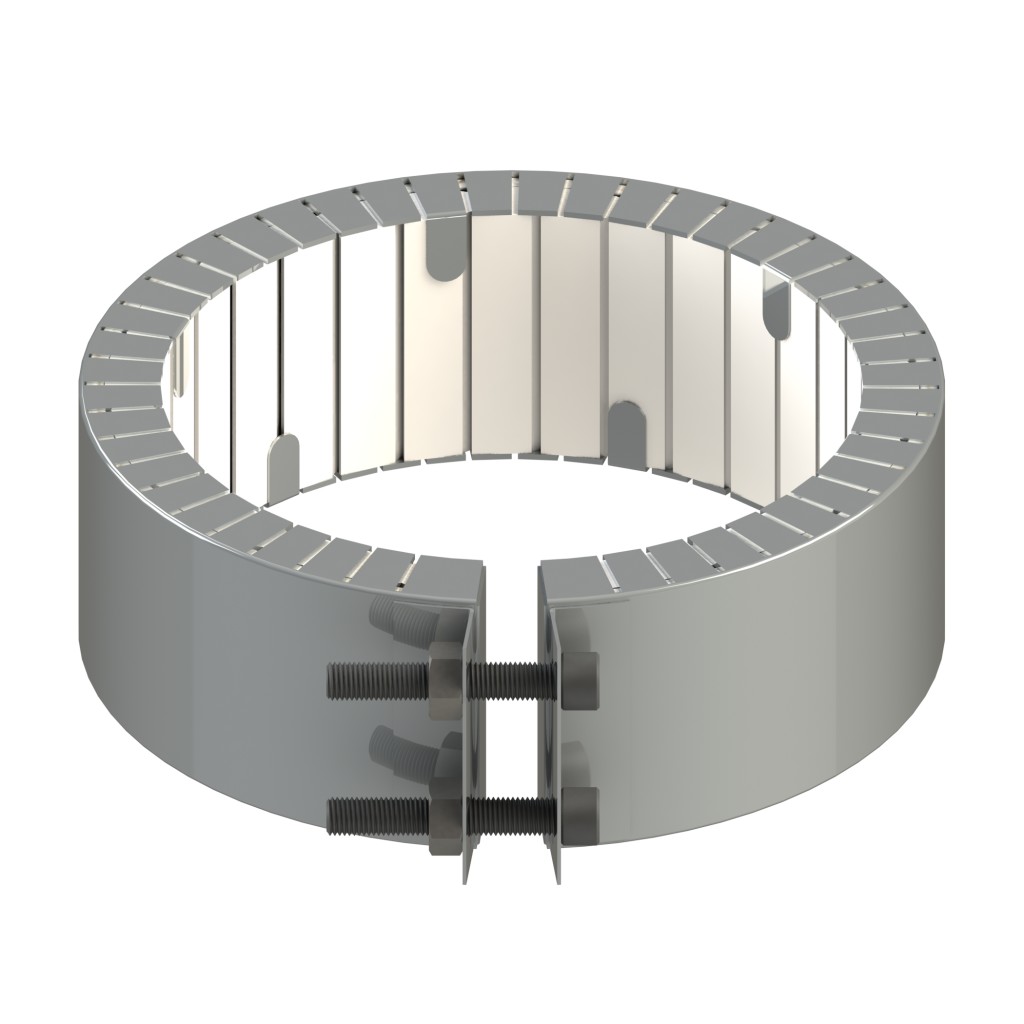

Built-in Strap Welded Barrel Nuts

Built-in Strap Welded Barrel Nuts on Ceramic Band Heaters

Built-in barrel Nuts are excellent clamping option for heaters with holes or cutouts.

No strap to loosen or adjust.

Mounting bracket with barrel nut lockup, with 1/4-20 screws. Can be supplied in any construction or termination variation.

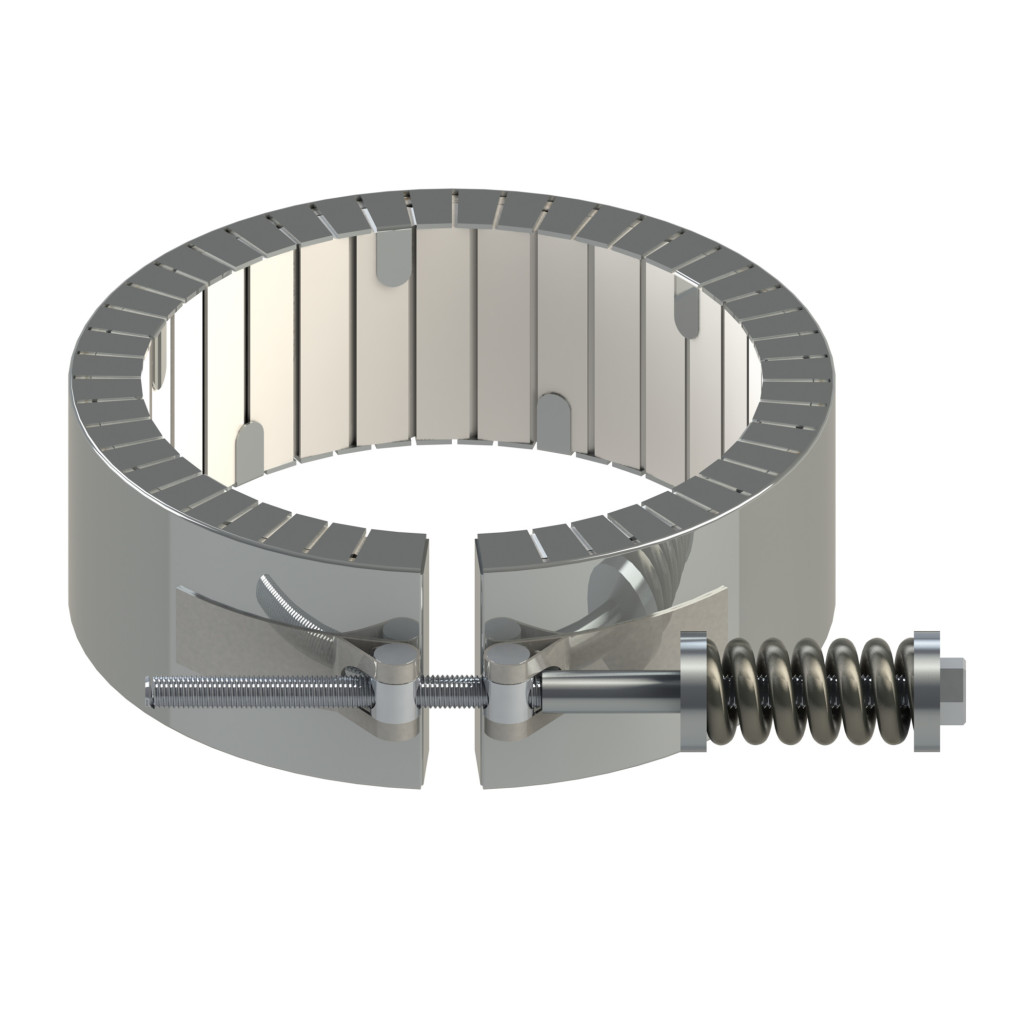

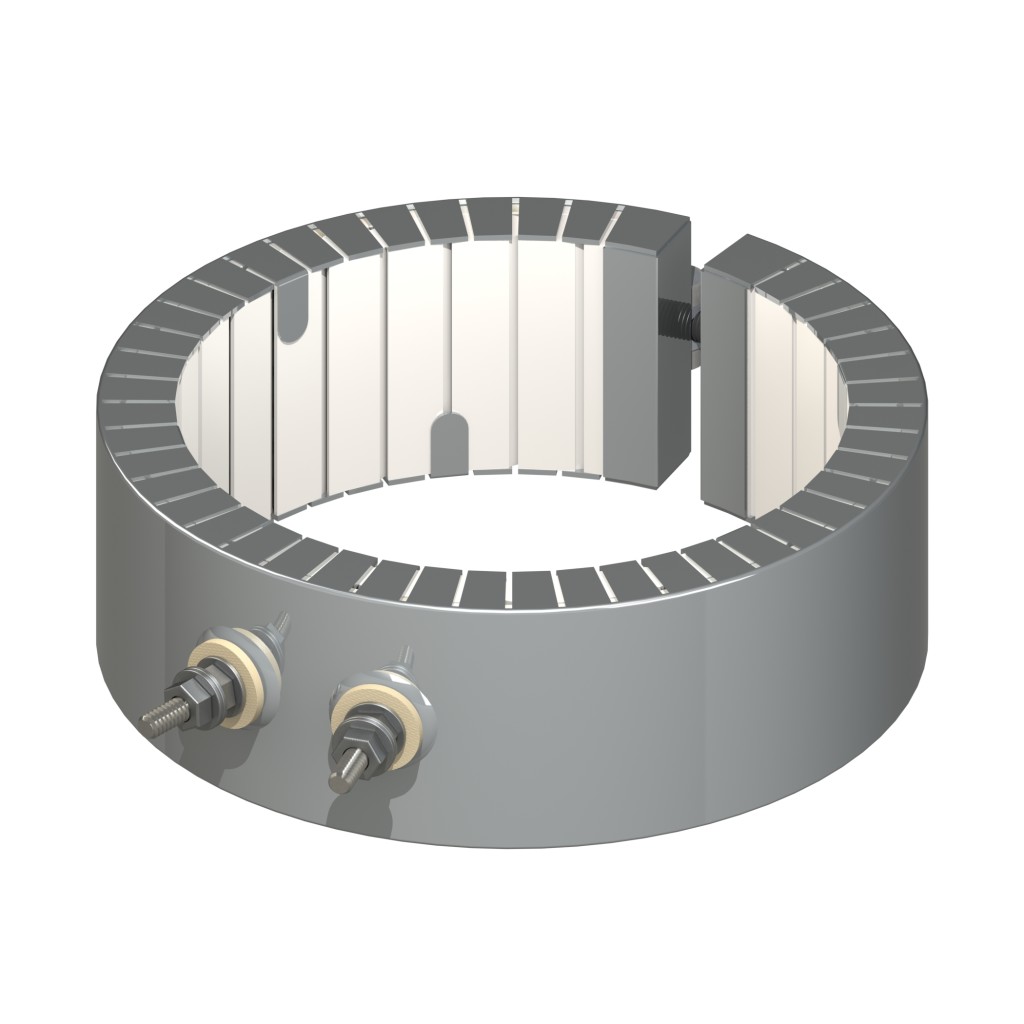

Clamping Spring Loaded Screw

Clamping Spring Loaded Screw on Ceramic Band Heaters

This barrel construction includes spring loaded clamps to flex during thermal expansion of the metals.

Bent Up Flange on Ceramic Band Heaters

Flange clamping is standard on all heaters as in standard construction description, unless otherwise noted.

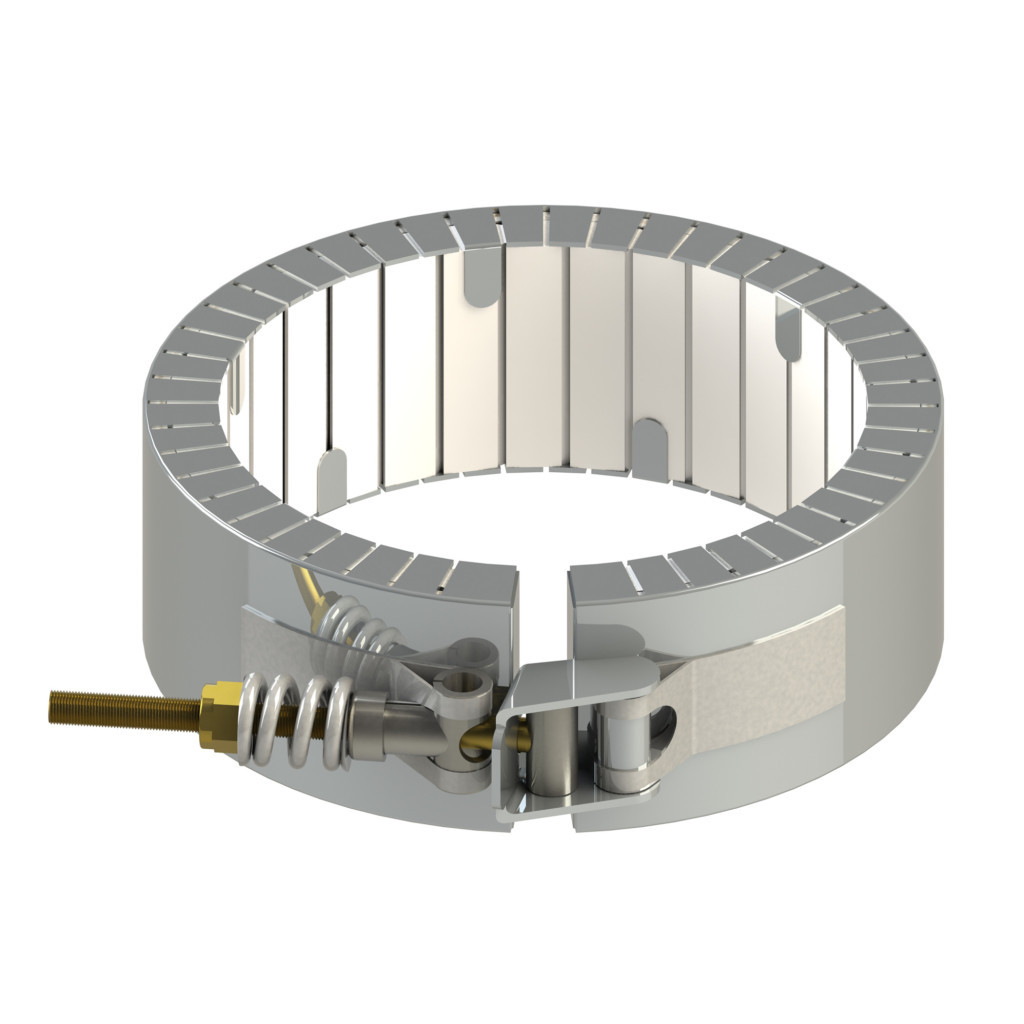

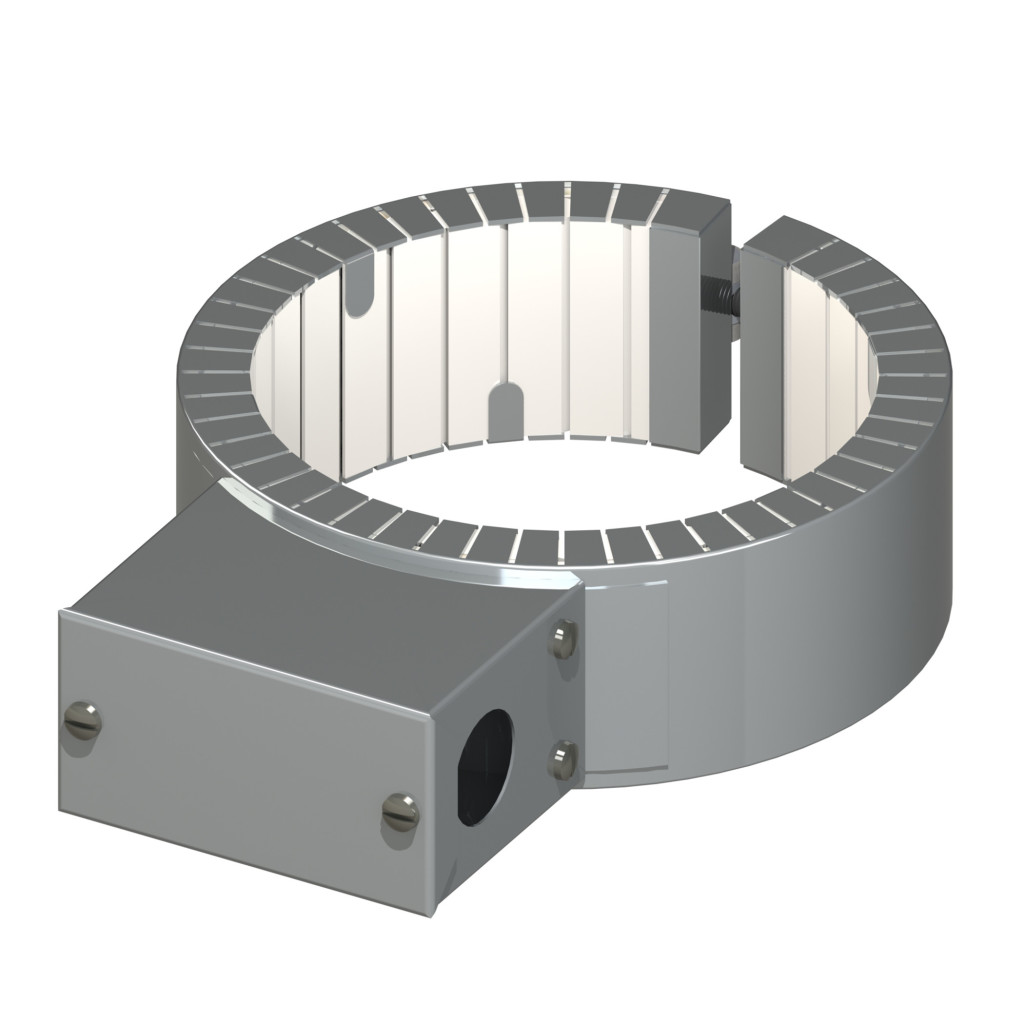

Latch and Trunion on Ceramic Band Heaters

Spring loaded latch & trunion is a quick release. Recommended l.D. 12" or greater.

This Latch and Trunion variation is ideal for Ceramic Band Heaters exceeding 12 ” in diameter regarding absorbing thermal expansion and for a secure installation on large bands.

You have several termination variations for our Ceramic Band Heaters.

Ceramic Beads Style on Ceramic Band Heaters

This Ceramic band style features protective ceramic beads (encasing the lead wires ) exiting the ceramic terminal box.

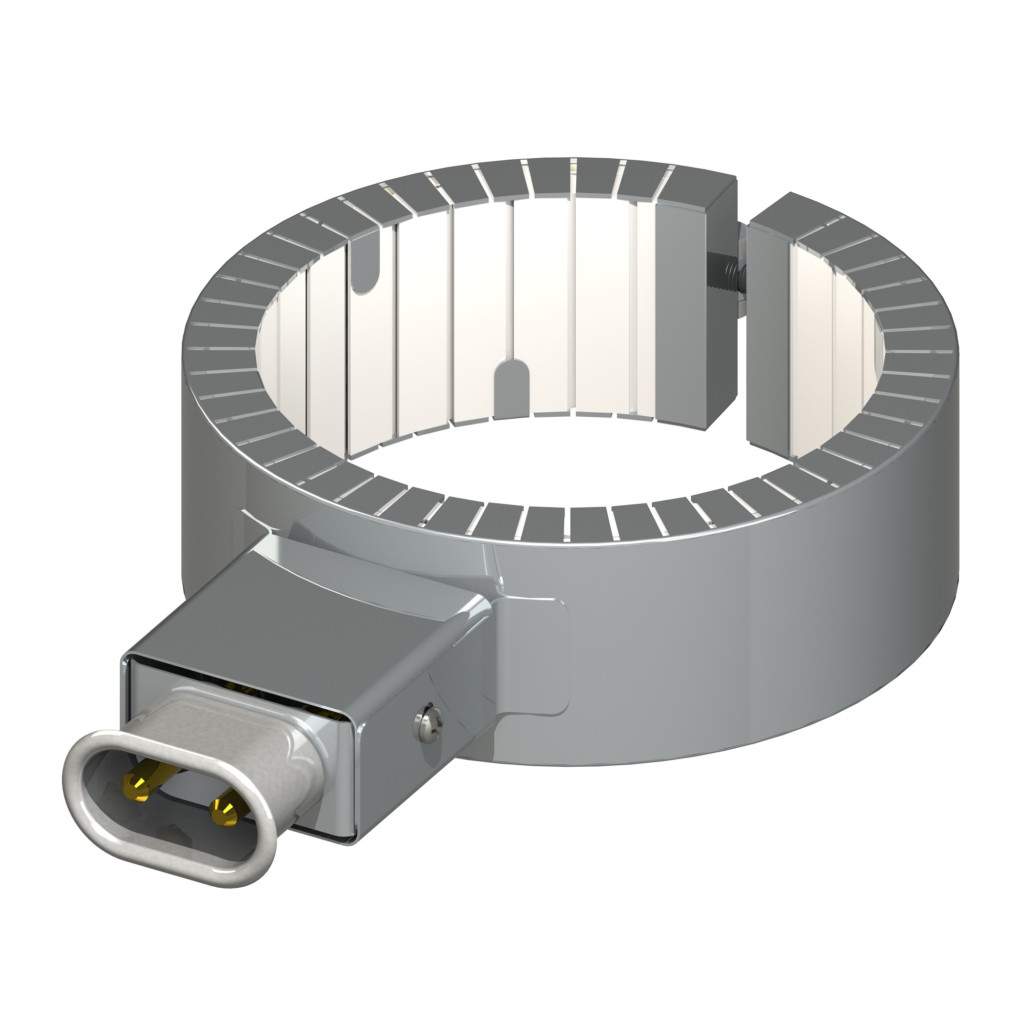

Ceramic Euro Plug with Box

Ceramic Euro Plug with Box on Ceramic Band Heaters

The Euro Plug (short for European) is an easy and safe application for applying power. The design combines high temperature and the quick disconnect plug to eliminate live wiring and exposed terminals.

Quick disconnect cup assembly is a safe way to provide power

to heater. Min Width 1-1/2", Max. AMPS 15 at 240V, MAX Volts 240.

When ordering Ceramic Euro Plug with Box, specify either a vertical or horizontal plug configuration.

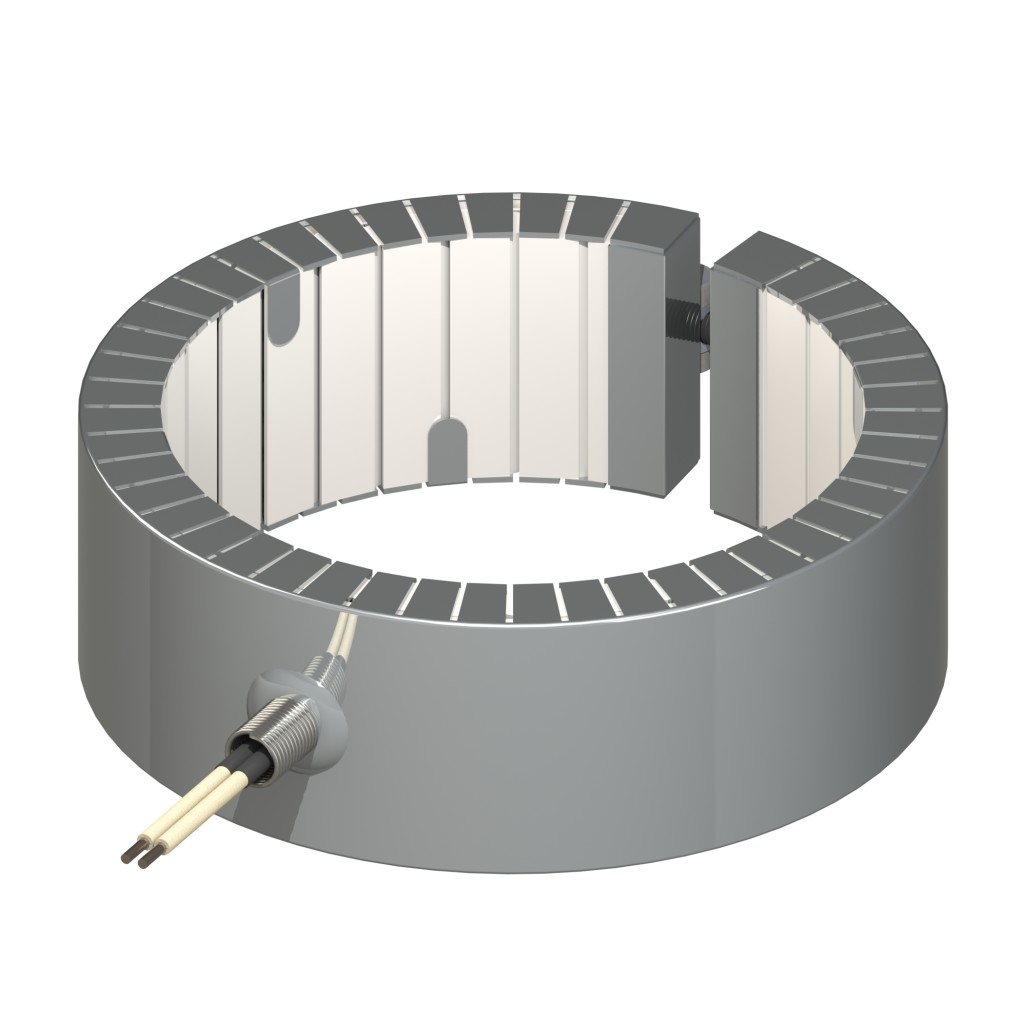

Ceramic Fiberglass Spring Relief

Ceramic Fiberglass Spring Relief on Ceramic Band Heaters

This Ceramic band includes fiberglass leads. The leads are covered and secured to the band by a spring relief component.

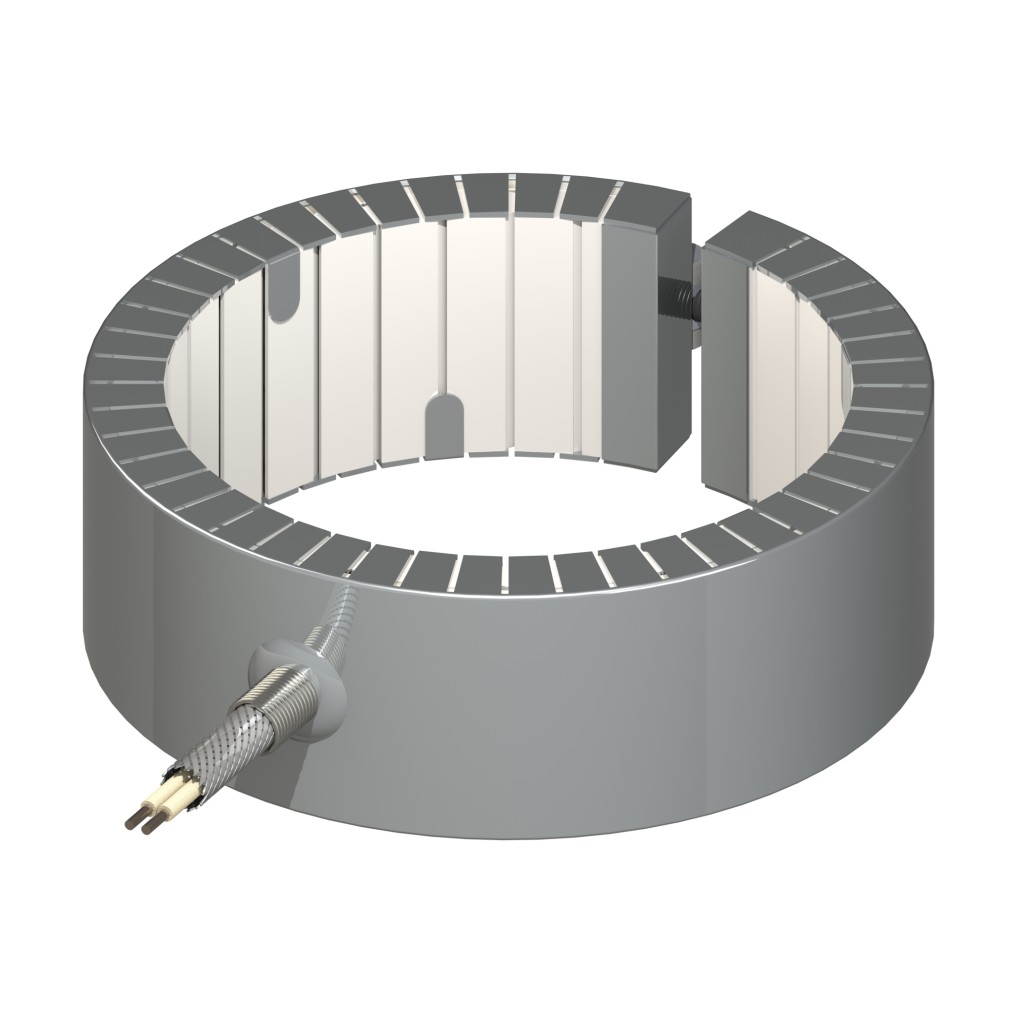

Ceramic Single Metal Braid Style

Ceramic Single Metal Braid on Ceramic Band Heaters

This variation bears a metal braid that provides significant flexibility and abrasion protection.

Protection of fiberglass leads, used to provide abrasion resistance, electrical grounding and where clearance is limited. Leads exit one point of heater surface through a strain relief. 10" braid over 12" leads. Min. I.D. 3", Min Width 1-1/2".

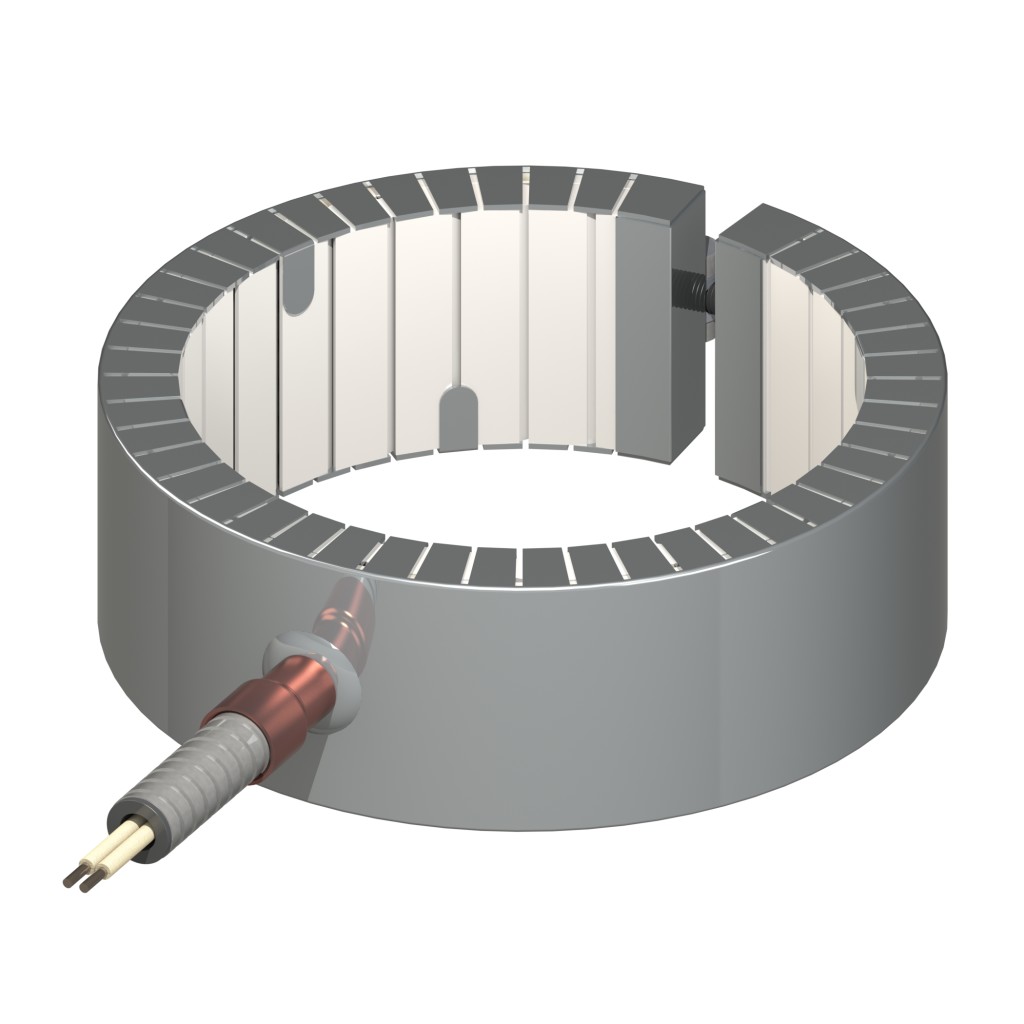

Ceramic Armor Cable Style

Ceramic Armor Cable on Ceramic Band Heaters

This style depicts fiberglass leads covered with a protective armor sleeve. The sleeve assembly is affixed to the band by a copper coupling.

Ceramic Post Terminals Vertical

Ceramic Post Terminals Vertical on Ceramic Band Heaters

This Style can be constructed with the terminals positioned either Vertically or Horizontally .

This design is the most common termination. Placed parallel with the width of heater with 10-24 or 1/4-20 post terminals. Located 180° from gap. Standard on all heaters greater than 3" width. Min I.D. 3", Min Width 3".

Be sure to specify the option you desire when you place your order.

Ceramic Post Terminals Horizontal

Ceramic Post Terminals on Ceramic Band Heaters

This Style can be constructed with the terminals positioned either Horizontally or Vertically .

This design is the most common termination. The terminal location is typically 180˚ from the gap, center line with length of heater with 10-24 or 1/4-20 post terminals.

Standard on widths under 3". Min l.D. 3"

Be sure to specify the option you desire when you place your order.

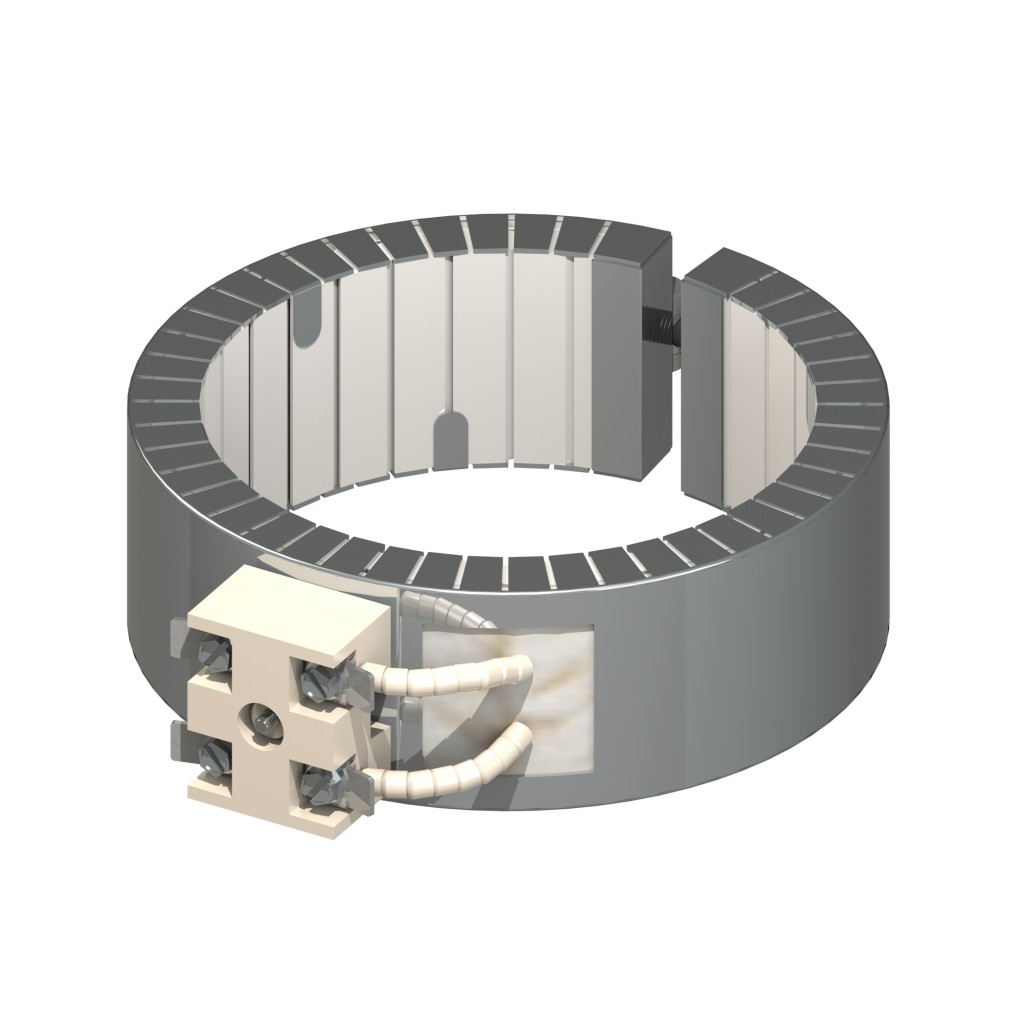

Ceramic T-Box on Ceramic Band Heaters

There are several lead options available for this ceramic T-Box style.

Designed in standard height of 1 3/4" high, with 5/8" conduit knockout for standard metal hose connections. Protects terminals from damage, spill leakage, grounding or short circuiting. Available for single or 3 phase construction.

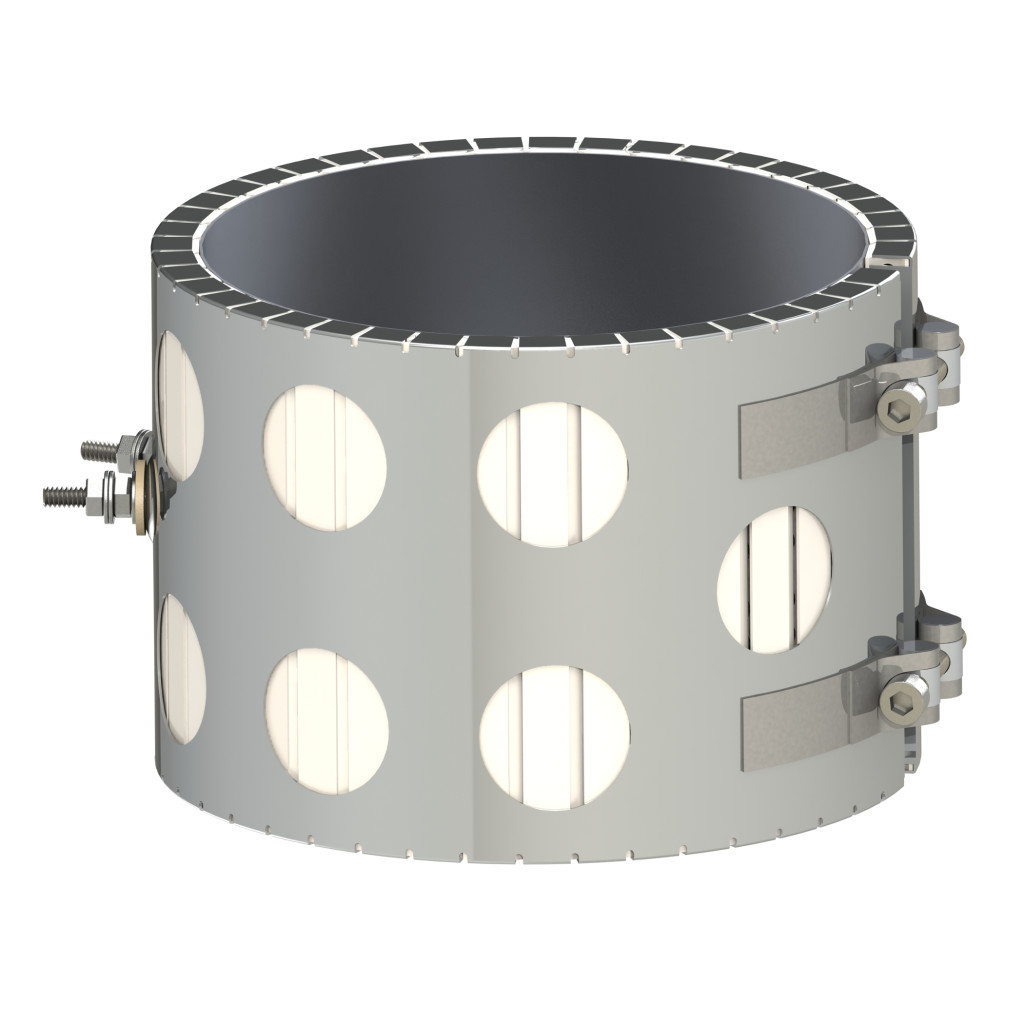

Ceramic Holes on Ceramic Band Heaters

This variation is without insulation. This style is suitable for air cooled applications.

Order Your Ceramic Band Heaters

Hampton Controls looks forward to serving you and supplying you with your Industrial Needs.

Every Ceramic Band is specially configured to your specifications.

Please fill out the information below and it is Important to NOTE: All fields are required.

Feel free to call us if you need any assistance at: 724-861-0150

See our Large Supply by Clicking on the Stock List Tab above or Configure your Band Heaters here.

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.