- Overview

- Description

- Termination

Options - Options

- Stock List

Custom Design

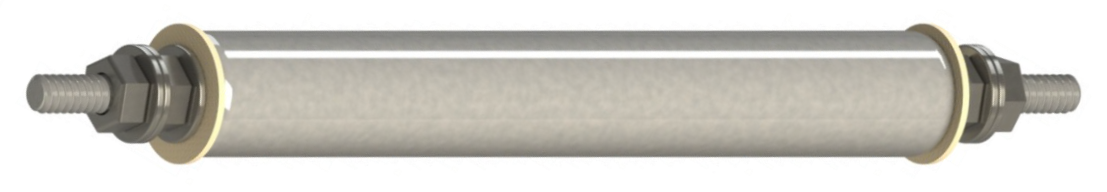

Cartridge Heaters by Hampton Controls

The engineers at Hampton Controls have developed a cartridge heater that exceeds the performance and durability of other cartridge heaters.

Through refinements in the swaging process, specially designed cores, careful selection of magnesium oxide fill, nickel chromium resistance wire, stainless steel tubing, and carefully controlled production processes, Hampton Controls Cartridge Heaters routinely outperform other cartridge heaters in difficult applications.

Our Cartridge Heaters are available in a wide variety of diameters and configurations. Choose from our 14,000+ stock heaters for immediate delivery or let the engineers at Hampton Controls design a unique heater for your special application.

Standard manufacturing times are normally less than 2 weeks.

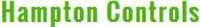

Cartridge Heater Construction

1. High Temperature Lead Wires for temperatures up to 550° C.

2. High Impact Ceramic Cap retards contamination and is suitable for high vibration applications. Deep holes in cap prevent fraying of leads when bent.

3. Nickel-Chromium Resistance Wire for maximum heater life, evenly wound for even heat distribution.

We set the Industry Standards

4. High Purity Magnesium Oxide fill selected for maximum dielectric strength and thermal conductivity, highly compacted for maximum heat transfer.

5. 304 Stainless Steel Sheath for oxidation resistance in a wide variety of environments. 316 Stainless Steel and Incoloy® are also available. Please consult the application guide in the back for help in determining which material is best for your application.

6. TIG Welded End Disc to prevent contamination and moisture absorption.

Hampton Control's Swaged Cartridge Heaters are the Industry Standard

- Designed and manufactured for temperatures up to 1600°F.

- Choose from one of our thousands of in stock models, or let our engineers design a custom heater for your application.

- Also available at a lower cost non-swaged versions.

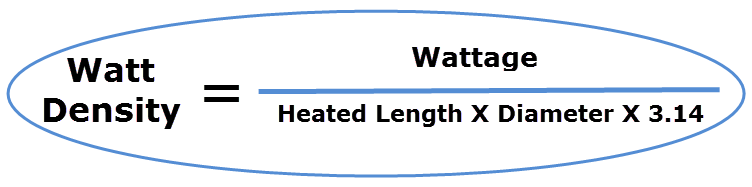

Watt Density Formula

- The tighter the hole fit, the better. Loose fit equals poor heat transfer and shorter heater life.

- Clearance is determined by taking the hole diameter and subtracting the heater diameter.

- Cycling reduces heater life and high cycling applications should use lower numbers.

- Please consult the following tables bleow for the maximum allowable watt density for heating metals.

Watt density is calculated with the following formula:

Maximum Watt Density for Heating Metals

Hole Clearance

Block Temperature in °F

Hole Clearance | 1200 | 1000 | 800 | 600 | 400 | 200 |

|---|---|---|---|---|---|---|

0.002 | 140 | 270 | 300 | 300 | 300 | 300 |

0.003 | 120 | 205 | 295 | 300 | 300 | 300 |

0.004 | 100 | 175 | 240 | 300 | 300 | 300 |

0.005 | 90 | 145 | 200 | 285 | 300 | 300 |

0.007 | 70 | 100 | 150 | 200 | 250 | 300 |

0.010 | 60 | 90 | 110 | 150 | 200 | 225 |

0.015 | 50 | 75 | 95 | 110 | 140 | 165 |

0.030 | 40 | 60 | 80 | 90 | 100 | 110 |

0.060 | 30 | 40 | 50 | 55 | 65 | 65 |

0.100 | 25 | 35 | 45 | 50 | 50 | 50 |

Standard Cartridge Heater Features

Diameters

1/8", 1/4", 6.5mm, 5/16", 8mm, 3/8", 10mm, 12mm, 12.5mm, 1/2", 13mm, 17/32", 5/8", 16mm, 17mm, 11/16", 19mm, 3/4", 20mm, 1"

Lengths

3/4" to 15 ft

Leads

550°C rated, other styles available

Sheath Material

304 stainless steel standard, 316 stainless steel and Incoloy 800 available.

Volts

480 volts max

Watts

Up to 400 watts per square inch

Agency Certifications

UL recognized (file no. E202904), CSA certified (file no. LR 109455-1)

Hampton Controls has many Cartridge Heater Options

There are literally hundreds of options that can be added to your Hampton Controls Cartridge Heater. Here are a few of our most popular modifications. If you don't see what your looking for Contact Hampton Controls for more info: 724-861-0150

- Diameters: - Includes Metric and Standard

- Sheath Materials: - Stainless Steel, Incoloy

- Termination options: - includes lead types, lead orientations, plugs, etc

- Lead-Wire-Options: - choose from a variety of lead wires

- End Seal-Options: - includes steatite, Teflon, mica, and lava end-pieces, and potting options

- Construction-Options: - includes electrical options, distributed wattage, double ended heaters, bent heaters, etc

- Add-Ons: - include NPT fittings, flanges, tabs, stops, special tips, etc

Termination Options for Cartridge Heaters

Swaged in Leads

Swaged in Leads for Cartridge Heaters

Swaged in leads are ideal for applications where there is a lot of movement or the leads must be bent sharp upon exiting the heater. Standard lead wire type is Duraflex wire, rated to 550C. Other lead wire types are available.

Crimped on Leads

Crimped on Leads for Cartridge Heaters

Crimped on leads are generally used where the temperature at the end of the heater exceeds the maximum rated temperature of the lead wire, Since the connection between the leads and power pins is made outside the heater, the unheated length at the lead end of the heater is kept to a minimum. Crimped on leads are not recommended for applications where the leads must be bent sharply near the heater, or in applications where the leads will be subject to a lot of flexing. The high temperature connectors are covered by 1-1/2" of 2500 volt silicone rubber coated fiberglass sleeving.

Post Terminals

Post Terminals for Cartridge Heaters

Post Terminals: (also called screw terminals or stud terminals are used in applications where easy lead replacement is desirable. They work great with ring terminals or fork terminals. Post terminals are only available on 1/2" diameter heaters and larger. Terminals are #6-32, other sizes are available.

Right Angle Leads

Right Angle Leads for Cartridge Heaters

Right Angle Leads: are ideal for applications where space is limited. leads are covered with silicon impregnated fiberglass sleeve where they exit the heater.

Stainless Steel Braid

Stainless Steel Braid for Cartridge Heaters

Stainless Steel Braid: provides excellent abrasion protection while allowing the leads to be bent in a tight radius. Because the braid is swaged in, it is extremely resistant to pulling out of the heater.

Right Angle Stainless Steel Braid

Right Angle Stainless Steel Braid for Cartridge Heaters

Right Angle Stainless Steel Braid: Right angle stainless steel braid offers the same advantages as swaged in stainless steel braid, but allows use in tight spaces. When ordering, please specify the overall length.

Stainless Steel Flexible Conduit

Stainless Steel Flexible Conduit for Cartridge Heaters

Stainless Steel Flexible Conduit: (also known as armor or hose) provides maximum lead protection from abrasion, but cannot be bent quite as sharply as stainless steel braid. Conduit is swaged into the heater for maximum durability.

Right Angle Stainless Steel Conduit

Right Angle Stainless Steel Conduit for Cartridge Heaters

Right Angle Stainless Steel Conduit: Right angle stainless steel conduit offers the advantages as swaged in stainless steel conduit but allows use in tight spaces.

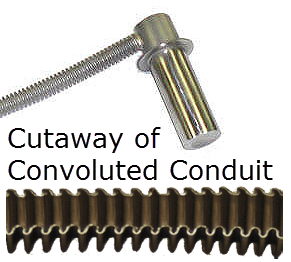

Convoluted Conduit

Convoluted Conduit for Cartridge Heaters

Convoluted Conduit: Unlike standard conduit, Convoluted Conduit is sealed and provides complete water resistance at any temperature, while forming a positive seal against contamination entering the heater.

It is available on standard 5/8" diameter cartridge heaters, 3/4" diameter cartridge heaters and Gala style heaters. In most cases, Convoluted Conduit is brazed directly to the heater.

Applications: Convoluted Conduit is best used in applications where moisture or contamination is an issue.

Cartridge Heaters Options

- Diameters

- Sheath Materials

- Cartridge Heater Leads

- End Seals

- Construction Options

- Add-ons

- Non-Swaged heaters

- Internal Thermocouples Types

Cartridge Heater Diameters

Cartridge Heaters by Hampton Controls are available in ALMOST unlimited diameters.

Nominal Diameter | Minimum Diameter | Maximum Diameter | Std. Lead Wire Gauge | Max Amps with Std. Lead wire | Max Lead Wire Gauge | Maximum Amps | Maximum Volts |

|---|---|---|---|---|---|---|---|

1/8” | 0.119 | 0.124 | 24 | 3.6 | 24 | 3.6 | 300 |

1/4” | 0.244 | 0.249 | 24 | 6 | 22 | 9 | 300 |

6.5 mm | 0.25 | 0.255 | 24 | 6 | 22 | 9 | 300 |

5/16” | 0.306 | 0.311 | 24 | 6 | 22 | 9 | 300 |

8 mm | 0.309 | 0.314 | 24 | 6 | 22 | 9 | 300 |

3/8” | 0.369 | 0.374 | 22 | 9 | 18 | 15 | 480 |

10 mm | 0.388 | 0.393 | 22 | 9 | 18 | 15 | 480 |

12 mm | 0.466 | 0.471 | 22 | 9 | 18 | 15 | 480 |

12.5 mm | 0.486 | 0.491 | 22 | 9 | 18 | 15 | 480 |

1/2” | 0.494 | 0.499 | 22 | 9 | 18 | 15 | 480 |

13 mm | 0.506 | 0.511 | 22 | 9 | 18 | 15 | 480 |

17/32 | 0.525 | 0.53 | 22 | 9 | 18 | 15 | 480 |

14 mm | 0.545 | 0.55 | 18 | 15 | 14 | 26 | 480 |

5/8” | 0.619 | 0.624 | 18 | 15 | 14 | 26 | 480 |

16 mm | 0.624 | 0.629 | 18 | 15 | 14 | 26 | 480 |

17 mm | 0.663 | 0.668 | 18 | 15 | 14 | 26 | 480 |

11/16” | 0.682 | 0.687 | 18 | 15 | 14 | 26 | 480 |

19 mm | 0.742 | 0.747 | 18 | 15 | 14 | 26 | 480 |

3/4” | 0.744 | 0.749 | 18 | 15 | 14 | 26 | 480 |

25 mm | 0.978 | 0.983 | 18 | 15 | 14 | 26 | 480 |

1” | 0.994 | 0.999 | 18 | 15 | 14 | 26 | 480 |

Sheath Materials for your Cartridge Heaters

Cartridge heaters are available with a standard 304SS sheath. In addition, 316 stainless steel and Incoloy 800 are optional. 304SS is excellent for most applications. However for extremely high temperature applications, Incoloy 800 is the better choice and for some corrosive environments 316SS is recommended. The chart below can help in selecting a sheath material.

E=Excellent G=Good F=Fair NR=Not Recommended

Fluid being heated | 304SS | 316SS | Incoloy | Max Watt Density | Max Temp (°F) |

|---|---|---|---|---|---|

Air to 1200 °F | E | E | E | | |

Air to 1400°F | G | G | E | | |

Air to 1600°F | F | F | G | | |

Acetic Acid | F | G | F | 40 | 180 |

Acetone | E | E | E | 20 | 130 |

Alcohol | F | E | E | 25 | 212 |

Asphalt | E | E | E | 4-10 | 200-500 |

Caustic Soda, 10% | E | E | E | 100 | 210 |

Degreasing Solution | G | E | E | 40 | 275 |

Electroplating Bath, Cadmium | E | E | E | 100 | 180 |

Electroplating Bath, Copper | E | E | E | 100 | 180 |

Ethylene Glycol | F | F | F | 30 | |

Freon | E | E | E | 2-5 | 300 |

Glycerin | E | E | E | 10 | 500 |

Kerosene | E | E | E | 25-30 | |

Molasses | E | E | E | 5 | 100 |

Nitric Acid (30% max) | E | E | E | 20 | 167 |

Oil (SAE 30) | F | F | NR | 20 | 250 |

Oil (SAE 50) | E | E | E | 10-15 | 250 |

Oil, Vegetable or Mineral | E | E | E | 30 | 400 |

Paraffin or Wax | E | E | E | 16 | |

Steam @ 300°F | E | E | E | 30 | 300 |

Steam @ 500°F | E | E | E | 25 | 500 |

Trichlorethylene | E | E | E | 30 | 150 |

Water, Distilled | F | F | F | 300 | 212 |

Water, Tap | E | E | E | 300 | 212 |

Cartridge Heater Leads

A Comparison Chart of the different types of Cartridge Heater Leads provided by Hampton Controls.

Wire Type | Maximum Recommended Temperature | Comments |

|---|---|---|

Duraflex | 550°C | Highest temperature rating, excellent, durable, user friendly. This is our standard lead wire. |

MGT | 450°C | Good high temperature wire. |

Ultralead | 450°C | Excellent, durable wire, good for high temperature applications. |

Teflon | 250°C | Good for areas where a small diameter wire is needed. |

Silicon Rubber | 200°C | Good moisture resistance. |

Braided Silicon Rubber | 200°C | Inexpensive wire, good for non-abrasive applications. |

SJO Cord | 90°C | Rubber jacket, resistant to oil and moisture. For use on 3/8” diameter and larger. |

End Seals for your Hampton Controls Cartridge Heaters

Descriptions of some of our End Seals

Ceramic End Seal:

- Excellent for high temperature applications up to 2500º F. Provides protection against some thicker liquids and dust, however it is not waterproof. Provides excellent mechanical strength and vibration resistance.

Teflon Seal End Seal:

- Teflon Seals are a mechanical seal constructed by compressing a solid piece of Teflon in the end of the heater creating a seal between the Teflon piece and sheath and a seal between the Teflon piece and the lead wire.

- Teflon lead wire is used in conjunction with the Teflon end seal. While Teflon has a temperature rating of 350º F., it softens slightly above 300º F. and can relax and compromise the seal.

- An unheated section of 1” at the end of the heater is generally required to avoid overheating the seal.

Mica End Seal:

- Excellent for high temperature applications up to 2600º F. Provides good protection from contamination.

Cement End Seal:

- Provides protection against some thicker liquids and dust, however it is not waterproof. It is also somewhat brittle and subject to cracking in high impact or high vibration applications. Rated to 2600º F.

Epoxy Potting End Seal:

- Provides a very good seal with excellent mechanical strength. However, it’s adherence to Teflon or silicone rubber lead wire is only fair. Bonds well to Duraflex lead wire. Rated to 600º F.

Epoxy-Lite Potting End Seal:

- Provides similar mechanical properties as epoxy potting, however it is Rated to 650º F.

RTV End Seal:

- RTV Potting, when used in combination with silicone rubber insulated lead wire, provides the best seal of all options.

- The down side to silicone is that it is limited to 500º F. and while extremely flexible, it is not as strong mechanically as other options.

- Although the RTV is rated for 500º F., silicone rubber lead wire is only rated to 400º F. An option is to use Duraflex lead wire instead. Duraflex is rated to 1000º F. and has a heavy silicone coating.

- While Duraflex is not sold as a waterproof wire, it performs very well in wet environments.

- Another option is to use crimped on leads, then the power pins are sealed where they enter the heater and the type of lead wire does not matter.

Lava End Seal:

- A swaged in lava plug protects the internal cartridge from contamination. Up to 1500 °F

Ceramic End Seal

Teflon End Seal

Mica End Seal

Cement End Seal

Epoxy End Seal

Epoxy-Lite Seal

Silicone Rubber

End Seal

Lava End Seal

Comparison Chart for End Seals

End Seal | Max | Moisture | Contamination | Mechanical | Vibration |

|---|---|---|---|---|---|

Ceramic End Piece | 2500° F | Poor | Poor | Excellent | Excellent |

Teflon End Piece | 300° F | Excellent | Excellent | Very Good | Excellent |

Mica Seal | 2500° F | Poor | Good | Average | Average |

Cement Potting | 1800° F | Poor | Fair | Good | Poor |

Epoxy Potting | 265° F | Good | Good | Excellent | Excellent |

Epoxy Lite Potting | 650° F | Fair | Very Good | Very Good | Excellent |

Silicone Rubber | 500° F | Excellent | Excellent | Fair | Excellent |

Lava Seal | 1500° F | Poor | Excellent | Good | Poor |

RTV | 400° F | Excellent | Fair | Average | Average |

SJO Cord | 250° F | Excellent | Fair | Excellent | Excellent |

Cartridge Heater Construction Options

Bent Heaters: An alternative to right angle leads.

Please note that the bend needs to be made in an unheated area of the heater.

Heater Diameter | Minimum Bend Radius |

|---|---|

1/4 | 1/2 |

5/16 | 1/2 |

3/8 | 1/2 |

1/2 | 3/4 |

5/8 | 1 |

3/4 | 1-1/4 |

Multi-Zone Heaters

Multi-Zone Heaters: Individually controlled heating zones. As many as 5 zones in 3/4" and 1" diameter heaters and 3 zones in other diameters. Leads are color coded for easy identification.

Cartridge Heater Double Ended Cartridge Heaters

Double Ended Heaters: Available with screw terminals, pins, and leads.

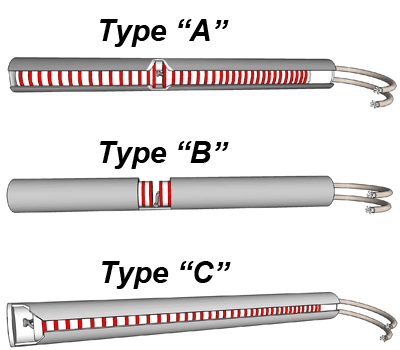

Distributed Wattage Cartridge Heaters

Distributed Wattage Cartridge Heaters are designed with the watt density varying along the length of the cartridge heater. The design compensates for heat losses along the edges of heated parts. This style is ideal for and typically used in platens and sealing bar applications.

Distributed Wattage Cartridge Heaters – When requesting this design, specify desired lengths in inches and wattage percentage.

Cartridge Heater Add-Ons

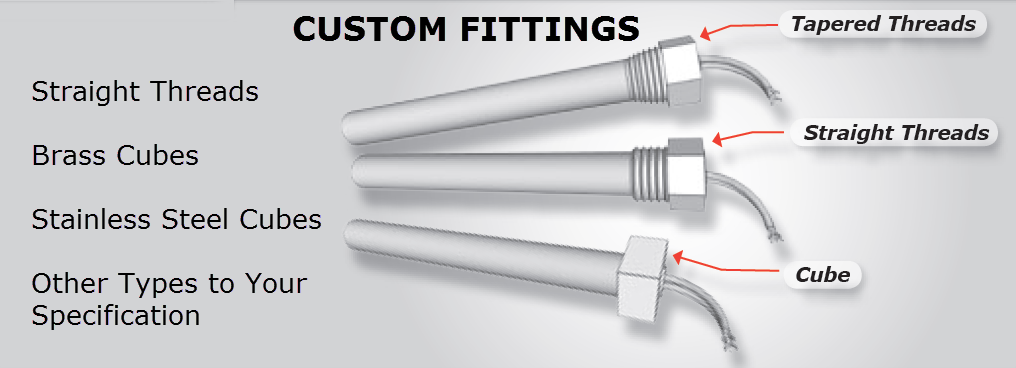

Hampton Controls offer a few of the options that can be added to swaged cartridge heaters and non swaged cartridge heaters.

Add-Ons | Description |

|---|---|

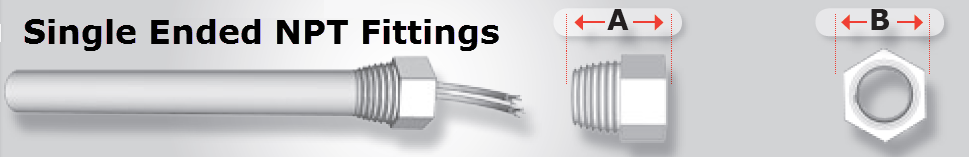

| Stainless Steel Fittings: Many different sizes available in both SINGLE and DOUBLE NPT fittings. "See Chart Below for Available Sizes" |

| Brass Fittings: Many different sizes available in both SINGLE and DOUBLE NPT fittings. "See Chart Below for Available Sizes" |

| Strain Relief: Provides extra support for leads. Great for applications with lots of flexing. |

| Flanges: Standard flange material is stainless steel. Flanges can be round or irregularly shaped. Contact Hampton Controls for standard and non-standard flange configurations. • Flanges are 1/16” thick |

Mechanical Stops Also

- Weld Beads

- Tab Stops

- Custom Round Flanges

- Custom Rectangular Flanges

- Ideal for preventing heaters from sliding too far into the hole

Specification Chart | ||||||

|---|---|---|---|---|---|---|

Heater Diameter | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 1" |

NPT Thread Size | 1/8" | 1/4" | 3/8" | 1/2" | 3/4" | 1" |

Brass "A" | .57 | .70 | .74 | .80 | .92 | 1.30 |

Brass "B" | .43 | .56 | .69 | .87 | 1.06 | 1.44 |

Stainless Steel "A" | .62 | .76 | .77 | .84 | .96 | 1.27 |

Stainless Steel "B" | .46 | .56 | .67 | .87 | 1.06 | 1.37 |

Specification Chart | ||||||

|---|---|---|---|---|---|---|

Heater Diameter | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 1" |

NPT Thread Size | 1/8" | 1/4" | 3/8" | 1/2" | 3/4" | 1" |

Brass "A" | .98 | 1.13 | 1.25 | 1.53 | 1.72 | 2.35 |

Brass "B" | .43 | .56 | .69 | .87 | 1.06 | 1.37 |

Stainless Steel "A" | .98 | 1.13 | 1.25 | 1.53 | 1.72 | CALL |

Stainless Steel "B" | .43 | .56 | .68 | .87 | 1.06 | CALL |

Non-Swaged Cartridge Heaters

Non-swaged cartridge heaters offer a cost effective solution where the performance of a swaged heater is not required.

Non-swaged heaters can be used at watt densities up to 45 watts per square inch and temperatures up to 1000°F. Non-swaged heaters offer tighter length tolerances than swaged heaters, making them ideal for applications such as platens where heaters are generally longer.

Non-swaged heaters can be built with 3 independent heat zones, distributed wattage, and/or internal thermocouples. Most of the lead configurations and options available for swaged cartridge heaters are also available for non-swaged cartridge heaters. Non-swaged heaters are not recommended for applications where there is is a lot of vibration or impact.

Non-Swaged Cartridge Heater Features

- Lead wires are UL rated to 550°C (1022°F)

- High temperature cement filling protects leads and internal parts. Epoxy and silicon rubber leads are available.

- Nickel chromium resistance wire stretched evenly throughout the length for even heat distribution.

- High purity MgO is vibratory filled for maximum heat transfer.

- 304 SS sheath for superior oxidation resistance.

- Welded end disc to prevent contamination and moisture absorption.

Non-Swaged Heater Specifications

Nominal Diameter | 5/8" | 3/4" | 1" |

Minimum Diameter | 0.167 | 0.742 | 0.992 |

Maximum Diameter | 0.624 | 0.749 | 0.999 |

Standard Lead with Gage | 18 | 18 | 18 |

Maximum Amps with Standard Lead Wire | 15 | 15 | 15 |

Maximum Lead Wire Gage | 16 | 16 | 16 |

Maximum Amps | 20 | 20 | 20 |

Maximum Volts | 600 | 600 | 600 |

Non-Swaged Heater Watt Density Recommendations

Block Temperature in °F

Hole Clearance | 1000 | 800 | 600 | 400 | 200 |

|---|---|---|---|---|---|

0.003 | 25 | 30 | 35 | 40 | 45 |

0.005 | 20 | 25 | 30 | 35 | 45 |

0.010 | 20 | 23 | 28 | 30 | 38 |

0.015 | 18 | 20 | 25 | 27 | 34 |

0.030 | 16 | 15 | 20 | 23 | 30 |

0.100 | 10 | 12 | 15 | 20 | 25 |

Cartridge Heater Internal Thermocouples Types

One optional feature on cartridge heaters are built in thermocouples.

- Built-in thermocouples can be of type “J” or type “K”, grounded or ungrounded and attached either at the disc end of middle of the cartridge.

- Internal thermocouples are available in a variety of styles, locations and types for your cartridge heater.

- Thermocouple lead wire is 24 ga. solid and unless otherwise specified, thermocouple leads are the same length as the power leads.

When ordering, please specify type, location, grounded or ungrounded (if not specified, you will receive grounded) and insulation material (if not specified, you will receive fiberglass).

Order Your Cartridge Heater

Hampton Controls looks forward to serving you and supplying you with your Industrial Needs.

Every Cartridge Heater is specially configured to your specifications.

Feel free to call us if you need any assistance at: 724-861-0150

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.