- Overview

- Description

- Docs & Specs

- Stock List

- Custom

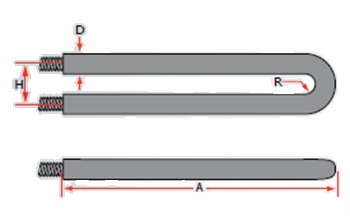

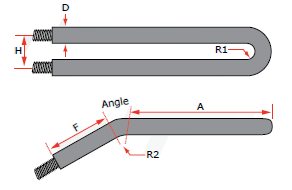

Designs - Bend

Formations

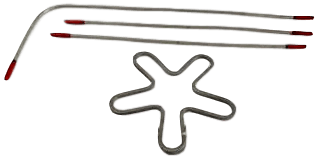

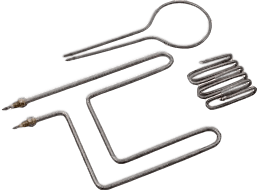

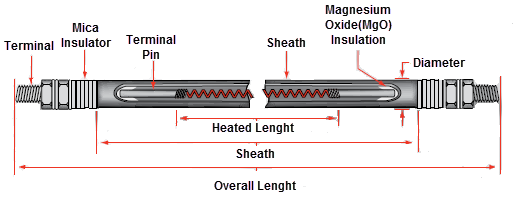

Tubular Heaters by Hampton Controls

The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually and configuration. The basic design consists of a helical coil of nickel-chromium resistance wire precisely centered in a metal sheath. The coil is surrounded by magnesium oxide powder which is vibration loaded to insure even density throughout the length of the heater.

This entire assembly is then reduced to the finished diameter, compacting the MgO and "freezing" the coil in the center of the heater. The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial and scientific applications.

- Easy installation with a uniform finish Can be formed by hand

- No special installation tools required

- Up to 75% sheath contact with round and square hotflex

- Rapid heat-up times

- 3-dimensional groove geometry possible

- Industry’s smallest bending radius

- Hotflex’s flexibility enables heat to be located where it is needed; an improvement over rigid cartridge heaters

- Stored in a straight condition to save storage space

- Patented technology ensures industry leading heat transfer

- heaters when recommended groove geometry is followed

- Minimal temperature difference between heater sheath and heated tool

- Reduced energy costs: tool mass can be reduced

- Liquid immersion (with threaded fittings /

flanges)

- Free Air / Radiant

- Clamped on

- Wrapped around

- Cast into aluminum,

bronze, or cast iron

- Installed into machine

grooves or drilled holes in

metal parts

Technical key features | |

|---|

Sheath material | stainless steel or Incoloy |

Sheath temperature

of heating element | max. 700 °C / 1290 °F |

Standard connection voltage | 230 V |

High voltage restistance* | 1000 V AC |

Insulation resistance* | 5 MOhm at 500 V DC |

Leakage current* | < 0.5 mA at 253 V AC |

Wattage tolerance | ± 10 % |

Length tolerance | ± 1.5 % |

*tested at environmental temperature | |

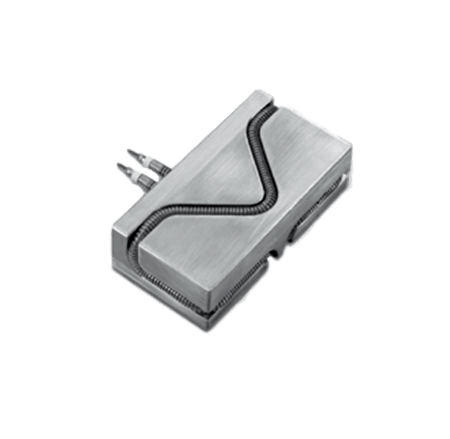

Installation example and Ideal heat transfer

Installation without special tools

Installed, round groove geometry

Options

- Bendable unheated zones

- Individual length

- Individual connection options

- Connection voltage from 12 V to 480 V

- Individual wattage

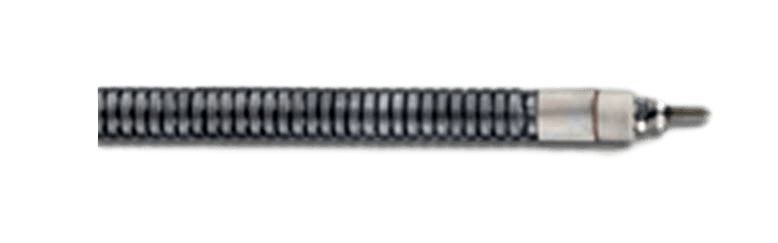

Hampton Flexible Tubular Heaters

Hampton Controls offers a full selection of tubular heaters and make the heating of complex platens, shapes, and machines, possible. The Hampton Tubular Heaters are completely flexible, and may be shaped at will around pipes, along platen paths, and other challenging shapes.

These are excellent replacements for traditional Tubular Heaters, which are not flexible and must be custom made in most cases.

Simplify your machine design, or reduce the maintenance time and cost by using flexible tubular heaters.

We offer the most expedited shipping of in stock flexible Tubular heaters in the market.

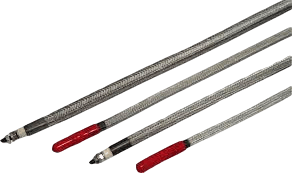

Flexible Tubular 6.5 mm

- Diameter: 6.5 +/-0.1 mm

- Sheath temperature of heating element: max. 700 C

- Wattage tolerance: +/-10%

- High voltage resistance (cold): 1,000 V-AC in

straight condition

- Sheath surface load: max. 10 W/cm2 according to application (depending on heated length)

- Minimum bending radius: Rmin = 6.5 mm (internal) Connection options: M 2.5 with set of nuts and washers made of stainless steel.

- Sheath material: stainless steel

- Connection voltage: max. 250 V, standard: 230 V

- Insulation resistance (cold): 5 M at 500 V-DC

- Leakage current (cold): 0.5 mA at 253 V-AC

- Extension factors: By bending and fitting the flexible Tubular becomes slightly longer. This extension is reproduce-able.

- Max. total length straight: 1,500 mm

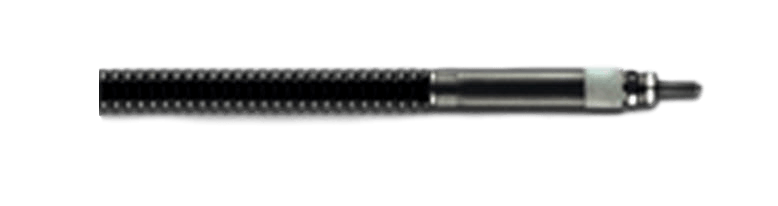

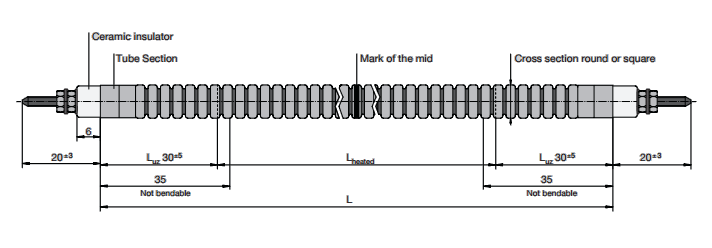

Flexible Tubular 8 mm

- Sheath material: Stainless Steel.Sheath temperature of heating element: Max. 700 C.

Voltage: 240 V.

- High voltage strength (cold) in straight condition: 1000 V-AC.

- Leakage current (cold) at 253 V-AC 0,5 mA

- Sheath surface load: Max. 15 W/cm2 (according to application).

- Unheated zones: Min. 30 mm/30 mm +/- 5 mm.

- Connection options: M4 with set of nuts and washers made of stainless steel.

- Note: Multi bending at the same point could damage the Flexible Tubular!

- Extension factors: by bending and fitting the Flexible Tubular, it becomes slightly longer. This extension is reproduceable.

- Not bendable zones: Min. 35 mm/35 mm.

- power tolerance (cold) +/- 10 %.

- Insulation resistance (cold) at 500 V-DC 5 M ohms

- Max. length straight 2600 mm

- Length tolerance straight: +/- 1,5 %

- Minimum bending radius (internal): R = 10 mm.

Flexible Tubular 8.5 mm

- Diameter: 8.5 +/-0.1 mm, 8.0 +/-0.1 mm resp. 8.2 +/-0.1 mm on option.

- Sheath material: stainless steel

- Sheath temperature of heating element: max. 700 C

- Connection voltage: max. 250 V, standard: 230 V

- Wattage tolerance: +/-10%

- High voltage resistance (cold): 1,000 V-AC in straight condition

- Insulation resistance (cold): 5 M at 500 V-DC

- Sheath surface load: max. 15 W/cm2 according to application (depending on heated length)

- Leakage current (cold): 0.5 mA at 253 V-AC

- max. total length straight: 2,600 mm

- Extension factors By bending and fitting the Flexible Tubular becomes slightly longer. This extension is reproduceable.

- Connection options: M 2.5 with set of nuts and washers made of stainless steel.

- Minimum bending radius: Rmin = 10 mm (internal)

Flexible Tubular 6x6

- Profile: 6 x 6 +/- 0.1 mm

- Sheath material: stainless steel

- Sheath temperature of heating element: max. 700 C

- Connection voltage: max. 250 V, standard: 230 V

- Wattage tolerance: +/- 10%

- High voltage resistance (cold): 1,000 V-AC in straight condition

- Insulation resistance (cold): 5 M at 500 V-DC

- Leakage current (cold): 0.5 mA at 253 V-AC

- Max. total length straight: 1,500 mm

- Extension factors: By bending and fitting the Flexible Tubular becomes slightly longer. This extension is reproduceable.

- Sheath surface load: max. 10 W/cm2 according to application (depending on heated length)

- Minimum bending radius: Rmin = 6.5 mm (internal)

- Connection options: M 2.5 with set of nuts and washers made of stainless steel.

Flexible Tubular 8 x 8

- Profile: 8 x 8 +/-0.1 mm,

- Sheath material: stainless steel

- Sheath temperature of heating element: max. 700 C

- Connection voltage: max. 250 V, standard: 230 V

- Wattage tolerance: +/- 10% High voltage resistance (cold): 1,000 V-AC in straight condition

- Leakage current (cold): 0.5 mA at 253 V-AC

- Max. total length straight: 2,600 mm

- Extension factors: By bending and fitting the Flexible Tubular becomes slightly longer. This extension is reproduceable.

- Insulation resistance (cold): 5 M at 500 V-DC

- Sheath surface load: max. 15 W/cm2 according to application (depending on heated length)

- Minimum bending radius: Rmin = 10 mm (internal)

- Connection options: M 2.5 with set of nuts and washers made of stainless steel.

Ceramic Terminal Conector

- *Pluging Heat*

- Temp. restist. 230°C / 445°F

- Short term max. 280°C / 535°F

- 14x21x25 mm / 5.51x8.27x9.84

Standard: threaded pins

M 2.5

- Option: M 4 from 8.0 mm

- with set of nuts and washers

Plain Ni-leads

- with ceramic beads insulation, up to 600 °C / 1110 °

Insulated Ni-leads

- Glass silk: up to 320 °C / 605 °F

- PTFE: up to 260 °C / 500 °F

- Silicon: up to 180 °C / 350 °F

- Option: eyelet connector M4

High temperature mineral fiber

- insulated Ni-leads,with ceramic sealed tube section

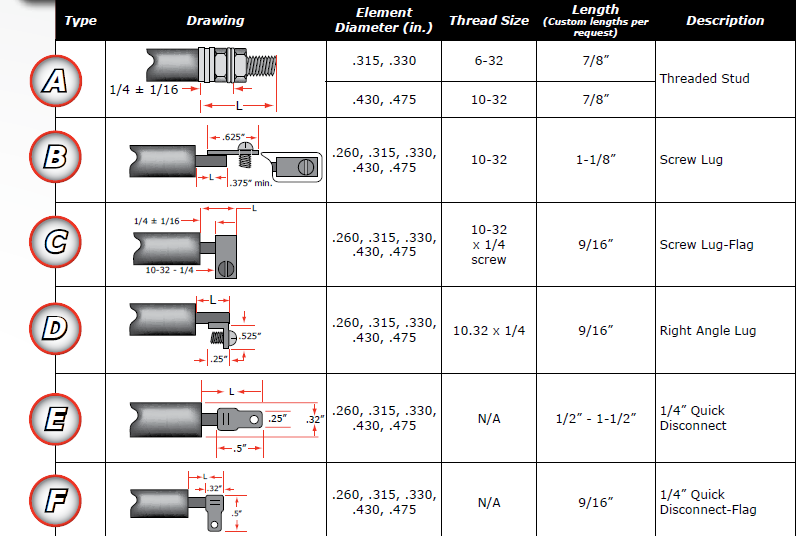

Terminations

Diameter

(in.) | Sheath Materials

Available | Maximum

Voltage | Maximum

Amperage | Maximum

Length

(in.) | Minimum

Factory

Bend Radius

(in.) | Minimum

Field

Bend

Radius

(in.) |

|---|

.200 | Incoloy | 240 | 12 | 98" | 1/4" | 3/4" |

.260 | Steel, Incoloy | 250 | 15 | 188" | 5/16" | 1-1/4" |

.315 | Steel, 316 SS, Incoloy | 480 | 30 | 294" | 3/8" | 1" |

.330 | Steel, 316 SS, Incoloy | 480 | 30 | 294" | 3/8"

| 1-1/4" |

.375 | steel, 316ss, Incoloy | 480 | 30 | 294" | 9/16" | 2" |

.430 | Steel, 304 SS, 316 SS

Incoloy | 600 | 40 | 312" | 7/16" | 1-3/8" |

.475 | Steel, 304 SS, 316 SS

Incoloy | 600 | 40 | 312" | 1/2" | 1-3/8" |

Sheath Temperature

Guidelines

Sheath Material | Sheath Temperature

(Max.) |

|---|

Steel | 750°F |

Stainless | 1200°F |

Incoloy | 1600°F |

Material Being

Heated | Maximum

Recommended

Watt Density | Recommended

Sheath Material |

|---|

Air to 750°F | 30 | Steel |

Air to 1200°F | 40 | 304 SS or 316 SS |

Air to 1600°F | 40 | Incoloy |

Tap Water | 60 | 316SS or Incoloy |

Distilled Water | 60 | 304SS, 316SS, or

Incoloy |

Deionized Water | 60 | 316SS |

Hot Runner Molds

(Manifolds) | 60 | 304SS or 316SS |

Light Oils, Greases,

Heat Transfer

Fluids | 23 | Steel |

Medium Weight

Oils | 15 | Steel |

Heavy Weight Oils | 8 | Steel |

Caustic Solutions | 23 | Incoloy |

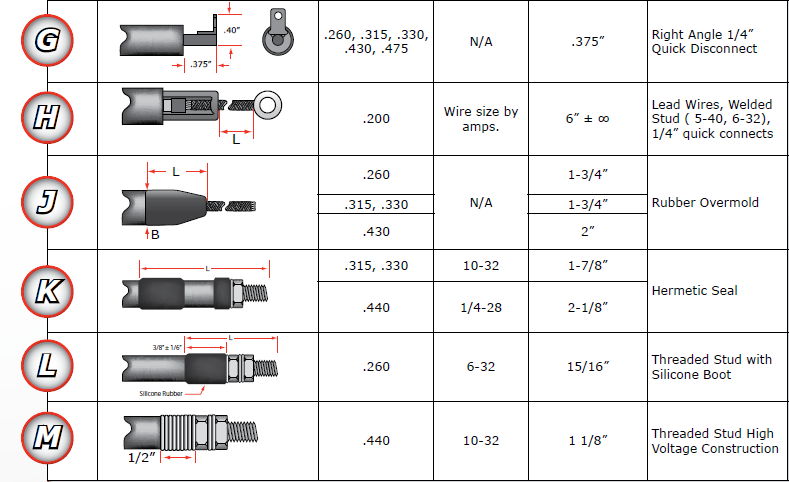

End Seals

Tubular heaters use Magnesium Oxide (MgO) as an insulator

between the heating coil and the sheath. MgO is hygroscopic,

and will absorb and retain water molecules from its

surroundings.

This is an undesired characteristic as any humidity inside the

heater will corrode the resistance wire, degrade the resistance

of the heater, and even allow an arc between the sheath and

the resistance wire.

To prevent moisture from affecting the performance of the

heater, a variety of end seals are available.

Listed below are our standard recommendations. Combinations

of these end seals are available as are other options not listed

here.

End Seal | Type | Max. Cont.

Use Temp. | Typical or General Usage / Application |

|---|

Cement | P | 2000 °F | Extremely high temperature applications, for low vapor

transmission rates |

Silicone Barrier | MS | 600 °F | Porous, moisture resistant, general usage on tubular products. |

Epoxylite | EX | 600 °F | Hermetic, long term stable insulation resistance. |

High Temp Silicone Rubber | VH | 450 °F | Moisture / Chemical Resistant. General Sealing. |

Silicone Rubber | V | 350 °F | Moisture / Chemical Resistant. General Sealing. |

Epoxy | E | 266 °F | Hermetic, long term stable insulation resistance. |

Rubber Molded End Seal | RU | 250 °F | Hermetic, long term stable insulation resistance. Full terminal |

Alternate Seals Available Upon Request

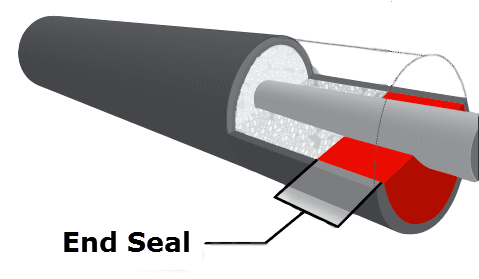

Threaded Fittings

- Threaded bulkhead fittings can be supplied on the terminal ends of

tubular elements.

- A gasket washer permits liquid tight installation in tank walls for

immersion heating of water, oil, and other liquids.

- Watertight gasket and lock nut are included.

Element Dia.

(in.) | Thread Size | Tank Wall Hole

Dia. | Thread Length | Hex A.F. | Rd.

Diameter | Specify

Material |

|---|

.260 | 7/16” - 20 | 15/32” | 5/8” | 5/8” | ----- | Stainless

Steel |

.315 | 1/2” - 20 | 17/32” | 1/2” | ----- | 3/4” | Stainless

Steel |

.430 | 5/8” - 18 | 21/32” | 13/16” | 7/8” | ----- | Stainless

Steel |

.475 | 5/8” - 18 | 21/32” | 13/16” | 7/8” | -----

| Stainless

Steel |

Other Options

- Brackets

- Locating Rings

- Washers

- “Bright Sheath Passivation”

+ Nitric Acid Bath + Glass

Bead Bright Finish

.315 inch Diameter

- 60W per square inch, 316SS

- 23W per square inch, Incoloy

- 23 W per square inch, Steel

Volts | Watts | Lenght (in.) | Heated Lenght (in.) | Unheated

(in., each end) | Part # |

|---|

120 | 500 | 12.50 | 8.50 | 2 | TU31L-0125A |

240 | 500 | 12.50 | 8.50 | 2 | TU31L-0125B |

120 | 750 | 16.75 | 12.75 | 2 | TU31L-0167A |

240 | 750 | 16.75 | 12.75 | 2 | TU31L-0167B

|

120 | 1000 | 21.00 | 17.00 | 2 | TU31L-0210A |

240 | 1000 | 21.00 | 17.00 | 2 | TU31L-0210B |

240 | 1250 | 25.00 | 21.00 | 2 | TU31L-0250A |

120 | 1500 | 29.00 | 25.00 | 2 | TU31L-0290A |

240 | 1500 | 29.00 | 25.00 | 2 | TU31L-0290B |

240 | 2000 | 38.00 | 34.00 | 2 | TU31L-0380A |

240 | 2500 | 46.00 | 42.00 | 2 | TU31L-0460A |

240 | 3000 | 55.00 | 51.00 | 2 | TU31L-0550A

|

240 | 4000 | 71.00 | 67.00 | 2 | TU31L-0710A |

.475 inch Diameter

- 48W per

square

inch, Incoloy

- 23W per

square

inch, Incoloy

- 23W per

square

inch, Steel

- 15W per

square

inch, Steel - 8W per

square

inch, Steel

Watts

| Length

(in.) | Heated Length

(in.) | Unheated Length

(in., each end) | 120V

| 240V

| 480V

|

|---|

1000 | 23.00 | 14.00 | 4.5 | TU48Y-0230A | TU48Y-0230B | TU48Y-0230C |

1500 | 30.00 | 21.00 | 4.5 | TU48Y-0300A | TU48Y-0300B | TU48Y-0300C |

2000 | 37.00 | 28.00 | 4.5 | TU48Y-0300A | TU48Y-0370B | TU48Y-0370C |

2500 | 47.00 | 35.00 | 6 | TU48Y-0470A | TU48Y-0470B

| TU48Y-0470C |

3000 | 54.00 | 42.00 | 6 | N/A | TU48Y-0540A | TU48Y-0540B |

4000 | 68.00 | 56.00 | 6 | N/A | TU48Y-0680A | TU48Y-0680B |

5000 | 82.00 | 70.00 | 6 | N/A | TU48Y-0820A | TU48Y-0820B |

6000 | 96.00 | 84.00 | 6 | N/A | TU48Y-0960A | TU48Y-0960B |

Recommended groove geometry

Type hotflex | Groove dimensions [mm] w x h |

|---|

6.0±0.1 | 6.1+0.1 x 7.1+0.1 |

Ø 6.5±0.1 | 6.0+0.1 x 6.5+0.1 |

Ø 8.0±0.1 | 7.7±0.05 x 8.0±0.1 |

8.0±0.1 | 8.1+0.1 x 9.1+0.1 |

Ø 8.2±0.1 | 7.9±0.05 x 8.2±0.1 |

Ø 8.5±0.1 | 8.2±0.05 x 8.5±0.1 |

Ø 10.0±0.1 | 9.7±0.05 x 10.0±0.1 |

Stock range Ø 6.5 mm

(230 V)

Stock range Ø 8.0 mm

(240 V*)

Stock ID | L [mm] | P [W] | | Stock ID | L [mm] | P [W] |

|---|

6500300 | 300 | 350 | | 6300400 | 400 | 795 |

6500350 | 350 | 400 | | 6300450 | 450 | 910 |

6500400 | 400 | 500 | | 6300500 | 500 | 1025 |

6500450 | 450 | 600 | | 6300550 | 550

| 1145 |

6500500 | 500 | 650 | | 6300600 | 600 | 1260 |

6500550 | 550 | 700 | | 6300650 | 650 | 1380 |

6500600 | 600 | 800 | | 6300700 | 700 | 1495 |

6500650 | 650 | 850 | | 6300750 | 750 | 1615 |

6500700 | 700 | 900 | | 6300800 | 800 | 1730 |

6500750 | 750 | 1000 | | 6300850 | 850 | 1845 |

6500800 | 800 | 1100 | | 6300900 | 900 | 1960 |

6500850 | 850 | 1200 | | 6300950 | 950

| 2080 |

6500900 | 900 | 1300 | | 6301000 | 1000 | 2195 |

6500950 | 950 | 1350 | | 6301050 | 1050 | 2316 |

6501000 | 1000 | 1400 | | 6301100 | 1100 | 2430 |

6501050 | 1050 | 1450 | | 6301150 | 1150 | 2545 |

6501100 | 1100 | 1500 | | 6301200 | 1200 | 2665 |

6501150 | 1150 | 1550 | | 6301250 | 1250 | 2780 |

6501200 | 1200 | 1600 | | 6301300 | 1300 | 2895 |

6501250 | 1250 | 1650 | | 6301350 | 1350

| 3015 |

6501300 | 1300 | 1700 | | 6301400 | 1400 | 3130 |

6501350 | 1350 | 1800 | | 6301450 | 1450 | 3245 |

6501400 | 1400 | 1900 | | 6301500 | 1500 | 3365 |

6501450 | 1450 | 2000 | | 6301550 | 1550 | 3480 |

6501500 | 1500 | 2100 | | 6301600 | 1600 | 3600 |

Stock ID | L [mm] | P [W] | | Stock ID | L [mm] | P [W] |

|---|

6100300 | 300 | 650 | | 6110500 | 500 | 780 |

6100350 | 350 | 750 | | 6110550 | 550 | 860 |

6100400 | 400 | 900 | | 6110600 | 600 | 950 |

6100450 | 450 | 1050 | | 6110650 | 650

| 1000 |

6100500 | 500 | 1150 | | 6110700 | 700 | 1100 |

6100550 | 550 | 1300 | | 6110750 | 750 | 1190 |

6100600 | 600 | 1450 | | 6110800 | 800 | 1250 |

6100650 | 650 | 1600 | | 6110850 | 850 | 1350 |

6100700 | 700 | 1750 | | 6110900 | 900 | 1430 |

6100750 | 750 | 1900 | | 6110950 | 950 | 1500 |

6100800 | 800 | 2050 | | 6111000 | 1000 | 1590 |

6100850 | 850 | 2200 | | 6111050 | 1050

| 1650 |

6100900 | 900 | 2350 | | 6111100 | 1100 | 1750 |

6100950 | 950 | 2500 | | 6111150 | 1150 | 1830 |

6101000 | 1000 | 2650 | | 6111200 | 1200 | 1900 |

6101050 | 1050 | 2800 | | 6111250 | 1250 | 1990 |

6101100 | 1100 | 2930 | | 6111300 | 1300 | 2070 |

6101150 | 1150 | 3060 | | 6111350 | 1350 | 2070 |

6101200 | 1200 | 3190 | | 6111400 | 1400 | 2150 |

6101250 | 1250 | 3320 | | 6111450 | 1450

| 2230 |

6101300 | 1300 | 3450 | | 6111500 | 1500 | 2300 |

6101350 | 1350 | 3580 | | -------- | -------- | -------- |

6101400 | 1400 | 3710 | | -------- | -------- | -------- |

6101450 | 1450 | 3840 | | -------- | -------- | -------- |

6101500 | 1500 | 3970 | | -------- | -------- | -------- |

Watts

| Length

(in.) | Heated Length

(in.) | Unheated Length

(in., each end) | 120V

| 240V

| 480V

|

|---|

1000 | 41.00 | 29 | 6 | TU48Y-0410A | TU48Y-0410B | TU48Y-0410C |

1500 | 56.00 | 44 | 6 | N/A | TU48Y-0560A | TU48Y-0560B |

2000 | 70.00 | 58 | 6 | N/A | TU48Y-0700A | TU48Y-0700B |

2500 | 85.00 | 73 | 6 | N/A | TU48Y-0850A

| TU48Y-0850B |

3000 | 99.00 | 87 | 6 | N/A | TU48Y-0990A | TU48Y-0990B |

4000 | 129.00 | 117 | 6 | N/A | TU48Y-1290A | TU48Y-1290B |

5000 | 158.00 | 146 | 6 | N/A | TU48Y-1580A | TU48Y-1580B |

Watts

| Length

(in.) | Heated Length

(in.) | Unheated Length

(in., each end) | 120V

| 240V

| 480V

|

|---|

500 | 24.00 | 15 | 4.5 | TU48S-0240A | TU48S-0240B | N/A |

750 | 31.00 | 22 | 4.5 | TU48S-0310A | TU48S-0310B | N/A |

1000 | 41.00 | 29 | 6 | TU48S-0410A | TU48S-0410B | TU48S-0410C |

1500 | 56.00 | 44 | 6 | TU48S-0560A | TU48S-0560B

| TU48S-0560C |

2000 | 70.00 | 58 | 6 | TU48S-0700A | TU48S-0700B | TU48S-0700C |

2500 | 85.00 | 73 | 6 | TU48S-0850A | TU48S-0850B | TU48S-0850C |

3000 | 99.00 | 87 | 6 | N/A | TU48S-0990A | TU48S-0990B |

4000 | 129.00 | 117 | 6 | N/A | TU48S-1290A | TU48S-1290B |

5000 | 158.00 | 146 | 6 | N/A | TU48S-1580A | TU48S-1580B |

Watts

| Length

(in.) | Heated Length

(in.) | Unheated Length

(in., each end) | 120V

| 240V

| 480V

|

|---|

500 | 29.00 | 22 | 3.5 | N/A | TU48S-0290A | N/A |

667 | 39.00 | 30 | 4.5 | N/A | TU48S-0390A | TU48S-0390B |

833 | 46.00 | 37 | 4.5 | N/A | TU48S-0460A | TU48S-0460B |

1000 | 54.00 | 45 | 4.5 | N/A | TU48S-0540A

| TU48S-0540B |

1333 | 69.00 | 60 | 4.5 | N/A | TU48S-0690A | TU48S-0690B |

1667 | 84.00 | 75 | 4.5 | N/A | TU48S-0840A | TU48S-0840B |

2000 | 98.00 | 89 | 4.5 | N/A | TU48S-0980A | TU48S-0980B |

2500 | 121.00 | 112 | 4.5 | N/A | TU48S-1210A | TU48S-1210B |

3000 | 143.00 | 134 | 4.5 | N/A | TU48S-1430A | TU48S-1430B |

Watts

| Length

(in.) | Heated Length

(in.) | Unheated Length

(in., each end) | 120V

| 240V

| 480V

|

|---|

333 | 35.00 | 28 | 3.5 | N/A | TU48S-0350A | N/A |

500 | 49.00 | 42 | 3.5 | N/A | TU48S-0490A | N/A |

667 | 65.00 | 56 | 4.5 | N/A | TU48S-0650A | TU48S-0650B |

833 | 79.00 | 70 | 4.5 | N/A | TU48S-0790A

| TU48S-0790B |

1000 | 93.00 | 84 | 4.5 | N/A | TU48S-0930A | TU48S-0930B |

1333 | 121.00 | 112 | 4.5 | N/A | TU48S-1210C | TU48S-1210D |

1667 | 149.00 | 140 | 4.5 | N/A | TU48S-1490A | TU48S-1490B |

Volts | Watts | Length (in.) | Heated Length

(in.) | Unheated

(in., each end) | Part # |

|---|

120 | 500 | 29.00 | 22.00 | 3.5 | TU31Y-0290A |

240 | 500 | 29.00 | 22.00 | 3.5 | TU31Y-0290B |

120 | 750 | 40.00 | 33.00 | 3.5 | TU31Y-0400A |

240 | 750 | 40.00 | 33.00 | 3.5 | TU31Y-0400B

|

120 | 1000 | 51.00 | 44.00 | 3.5 | TU31Y-0510A |

240 | 1000 | 51.00 | 44.00 | 3.5 | TU31Y-0510B |

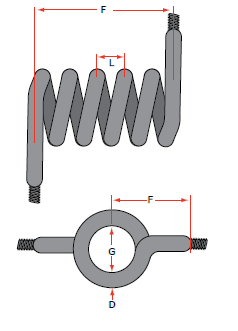

Dimensions:

Depending on the number of bends the hotflex length can increase up to 1 %.

Type | L Min

[mm] | L Max

[mm] | Tube section

Max [mm] | Min. bending

radius internal

| max. Sheath surface

load [W/cm2] | max. wattage

[W] at 230 V

|

|---|

6.0 | 300 | 1.800 | 24 | 6.5 | 10 | 2190 |

6.5 | 300 | 1.800 | 24 | 6.5 | 10 | 2190 |

8.0 | 300 | 2.600 | 10 | 10 | 15 | 5200 |

8.0 | 300 | 2.600 | 10 | 10 | 15

| 5200 |

8.2 | 300 | 2.600 | 10 | 10 | 15 | 5200 |

8.5 | 300 | 2.600 | 10 | 10 | 15 | 5200 |

10.0 | 300 | 2.600 | 10 | 10 | 12.5 | 5200 |

Volts | Watts | Length (in.) | Heated Length

(in.) | Unheated

(in., each end) | Part # |

|---|

120 | 250 | 15.00 | 11.00 | 2 | TU31S-0150A |

240 | 250 | 15.00 | 11.00 | 2 | TU31S-0150B |

120 | 350 | 19.00 | 15.00 | 2 | TU31S-0190A |

240 | 350 | 19.00 | 15.00 | 2 | TU31S-0190B

|

120 | 500 | 26.00 | 22.00 | 2 | TU31S-0260A |

240 | 500 | 26.00 | 22.00 | 2 | TU31S-0260B |

120 | 750 | 37.00 | 33.00 | 2 | TU31S-0370A |

240 | 750 | 37.00 | 33.00 | 2 | TU31S-0370B |

120 | 1000 | 48.00 | 44.00 | 2 | TU31S-0480A |

240 | 1000 | 48.00 | 44.00 | 2 | TU31S-0480B |

240 | 1250 | 59.00 | 55.00 | 2 | TU31S-0590A |

120 | 1500 | 70.00 | 66.00 | 2 | TU31S-0700A

|

240 | 1500 | 70.00 | 66.00 | 2 | TU31S-0700B |

Order Your Tubular Heaters

Hampton Controls looks forward to serving you and supplying you with your Industrial Needs.

Feel free to call us if you need any assistance at: 724-861-0150

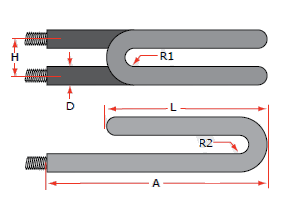

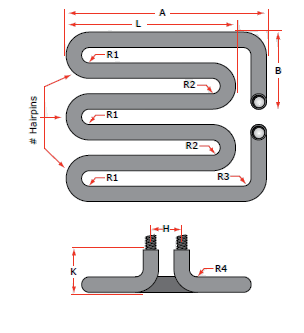

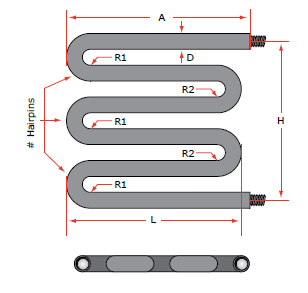

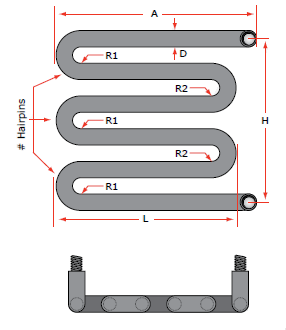

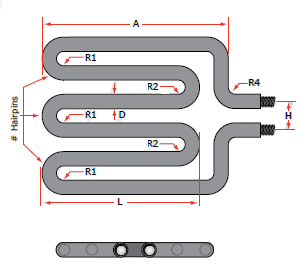

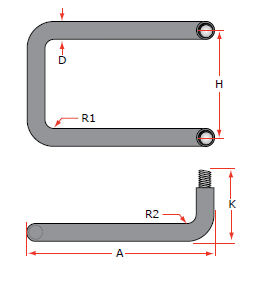

- Type 1

- Type 2

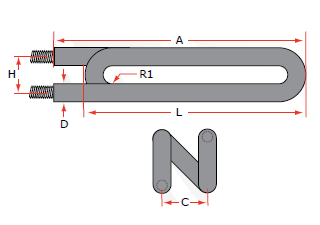

- Type 3

- Type 4

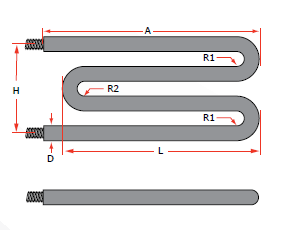

- Type 5

- Type 6

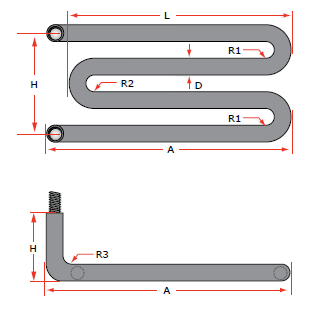

- Type 7

- Type 8

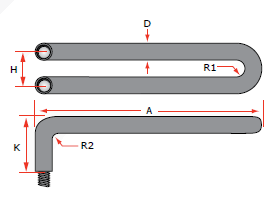

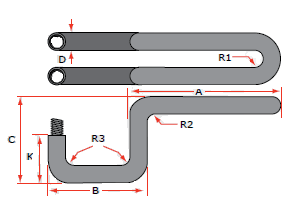

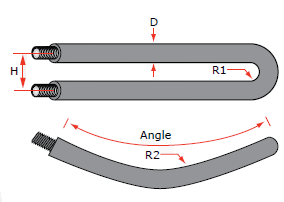

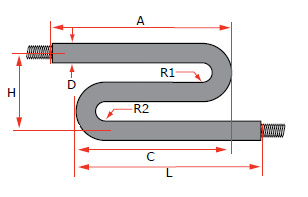

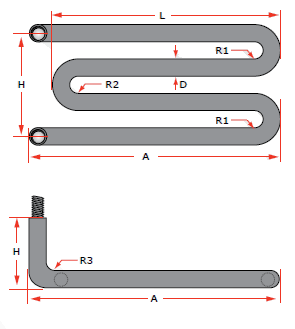

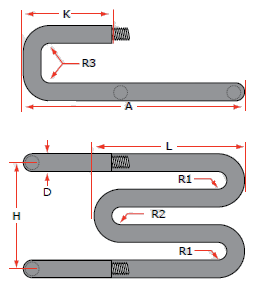

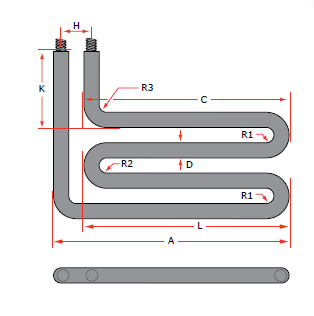

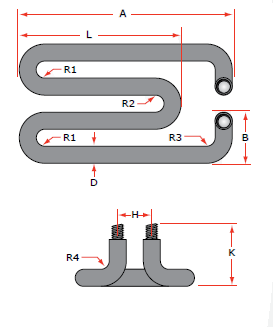

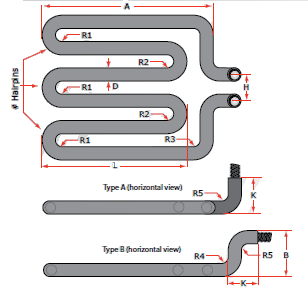

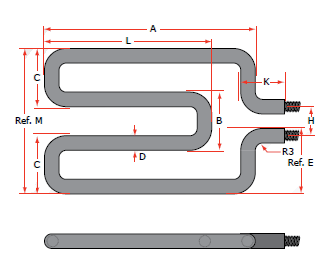

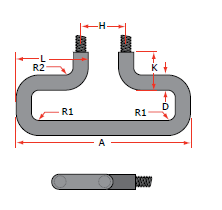

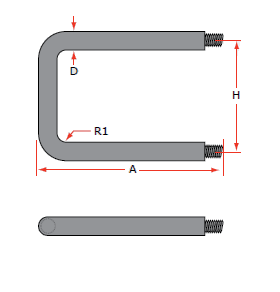

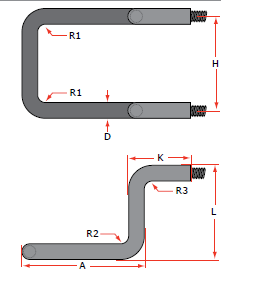

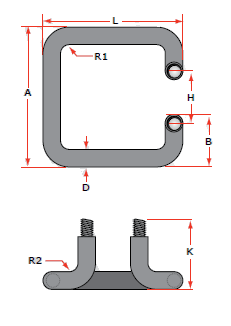

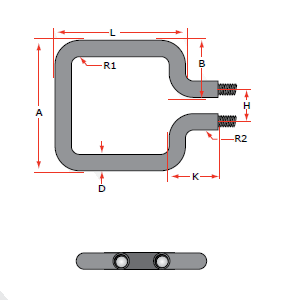

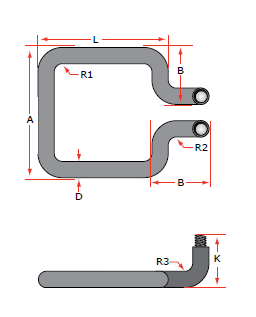

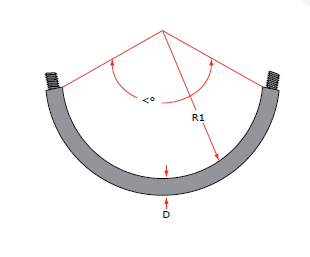

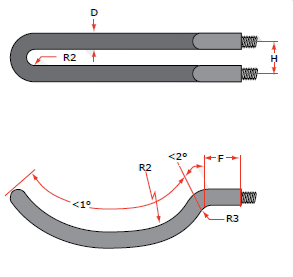

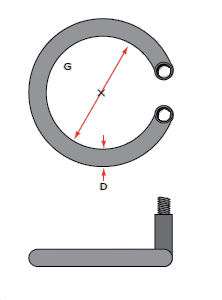

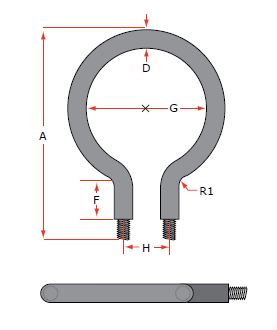

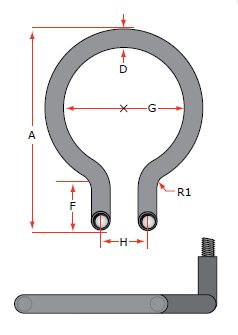

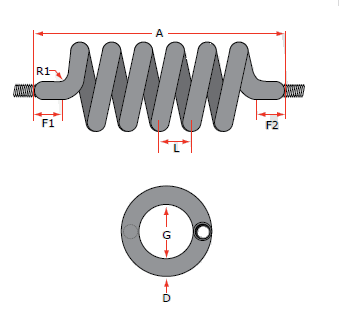

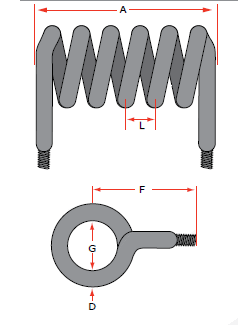

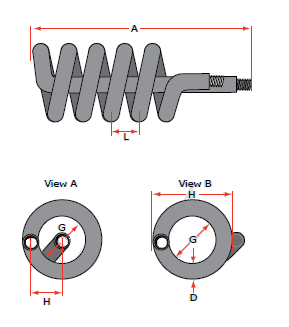

When possible, please provide a drawing to our design department to insure that heaters are manufactured to your

specifications.

If you do not have a drawing, you may choose one of the following standard configurations and supply us with the dimensions

shown. Please see page 2 for minimum bending radiuses.

- type 9

- Type 10

- Type 11

- Type 12

- type 13

- Type 14

- Type 15

- Type 16

- Type 17

- Type 18

- Type 19

- Type 20

- Type 21

- Type 22

- Type 23

- Type 24

- Type 25

- Type 26

- Type 27

- Type 28

- Type 29

- Type 30

- Type 31

- Type 32

- Type 33

- Type 34

- Type 35

- Type 36

See our Large Supply by Clicking on the Stock List Tab above.

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.