- Overview

- Description

- Docs &

Specs - Stock List

- Options

- Mounting

Methods - Custom

Design

Silicon Rubber Heaters

Flexible Heaters, Silicon Rubber Heaters, Drum Heaters, Kapton Heaters, Neoprene Heaters

Flexible heaters from Hampton Controls are just what the name implies; thin, bendable

and shaped to fit your equipment.

You can use your imagination to apply heat to the

most complex shapes geometries conceivable without sacrificing efficiency or

dependability.

Sheath Material | Typical Max. | Watt Densities | Suggested | Watt Densities | Max. Operating Temperatures |

|---|---|---|---|---|---|

| W/cm2 | W/in 2 | W/cm2 | W/in 2 | |

Silicone Rubber | 12.4 | 80 | 0.78 | 5 | 260° C (500° F) |

Polymide (Kapton) | 12.4 | 80 | 0.78 | 5 | 200° C (390° F) |

HT Foil | 17.0 | 110 | 3.1 | 20 | 595° C (1100° F) |

Neoprene | 1.7 | 11 | 0.31 | 2 | 120° C (250° F) |

Applications

- Medical equipment such as blood analyzers, respritory therapy units and hydrotherapy baths

- Freeze protection for military hardware, aircraft instrumentation and hydraulic equuipment

- Battery heating

- Food service equipment

- Factory bonding and subassemblies

- Any application requiring a flexible shape or design

Silicon Rubber Heaters offer a very high watt density while maintaining flexibility. Good for heating drums, de-icing vending machines, atms, aircraft, cars, and maintaining a comfortable temperature in medical equipment, such as CAT scanners.

- Hampton Controls Heater flexible heaters provide outstanding performance in applications up to 450°F.

- Design versatility permits special heat profiles,complex shapes and installation on a variety of surfaces.

- They are not affected by vibration, flexing, or repeated mechanical shock.

- Silicon Rubber Heaters has a high dielectric strength, is non-toxic, and flame retardant.

- Perfect for heating 55 gallon drums.

Silicon Rubber Heaters

Design and construction

Hampton Controls Silicon Rubber Heaters with wire-wound elements provide an excellent source for uniform heat especially on challenging shapes or applications with flexing or vibration.

The wire wound element consists of high temperature resistance wire wound around a fiberglass core for added support and flexibility while still allowing for expansion and contraction during heat up and cool down.

The element is laid out in a computer designed pattern to provide maximum heat transfer and temperature uniformity. After the element is laid out, it is vulcanized between two sheets of silicon rubber until they become one.

The silicon rubber sheets also have a layer of fiberglass for added strength and tear resistance. The same vulcanization process is used to attach the power leads and cord sets to the heater winding.

Operating conditions include vacuum applications, high moisture areas and outdoor applications. Silicon Rubber Heaters are also used in applications involving oils, solvents, radiation and environmental conditions

Applications

- Condensation prevention

- Freeze protection

- Food service

- Aerospace industry

- Heated platens

- Medical services

- Semiconductor Industry

- Heating of pipes

- Composite curing

- Irregular shapes

Standard Specifications

Voltage: 12V to 480V, AC or DC

Length: 1” to 120”

Width: 1” to 36”

Thickness: 0.060” (Other sizes available on request)

Lead Wire: 22 ga. Teflon (other sizes and insulation materials available on request)

Operating Temperature: -70° to 450°F

Wattage Tolerance: + 5%, - 10%

Standard Specifications

Maximum recommended watt density for standard wire wound Silicon Rubber Heaters is 5 watts/sq. in. Please note that higher watt densities are only recommended for very specific conditions. Please consult the chart below to determine the maximum watt density for your application. Using lower than recommended watt densities will result in increased heater life.

Suggested Maximum Watt Density Per Attachment Method

Watt Density w/sq. in. | Factory | PSA |

|---|---|---|

5 | 420°F - 356°F | 350°F - 335°F |

10 | 356°F - 266°F | 335°F - 248°F |

15 | 266°F - 158°F | 248°F - 140°F |

20 | 158°F - 68°F | 140°F - 32°F |

25 | 40°F - 68°F | 32°F - 49°F |

Silicon Rubber Heaters

Design Options

Hampton's Heater offers several design options to meet various application requirements:

- Ground Mesh

- Silicon Rubber Sponge insulation

- Round Heaters

For grounding purposes a second layer of insulating material and a conductive grid can be added to the heater. The heater comes with a ground wire.

To improve heater efficiency, 1/16”, 1/8”, 1/4”, 3/8” or 1/2” insulation can be bonded to the outside of the heater. Closed cell silicon sponge is extremely flexible and has a Temperature range of –103 F to 450 F.

Round shapes are also available. Round heaters are best attached to tooling with PSA

- Various Shapes for various aplications

- Other Options

- Wire wound Silicone Rubber Heaters

Odd shapes are available to fit those hard to heat devices. Holes and cutouts help fit those irregular shaped tools

Contoured parts can also be heated with silicone rubber heaters.

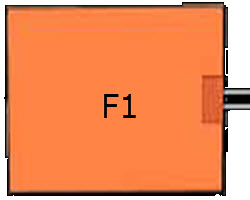

- Enclosure heaters are used to maintain temperature in any type of electrical box. Typical applications include ATM’s, control boxes, traffic signals, utility boxes, cabinets and switch gear.

- Enclosure heaters are excellent for controlling humidity or moisture within an electrical box. Silicon rubber heaters are typically mounted to an aluminum plate and have an ambient sensing thermostat.

- The plate has a flange for easy mounting to the tool. Minimum heater widths with a thermostat is 2”. Lengths are available to 40”. Aluminum plates are ½” wider than the heater. See stock page.

Other Options

- Dual Voltage

- Three Phase

- Distributed Wattage

- Thermocouples

- Thermostats

- Temperature cut-off

- Pull tabs

Wire wound Silicon Rubber Heaters

Hampton's Heater flexible heaters provide outstanding performance in applications

up to 450°F under a variety of operating conditions.

Properly applied silicon rubber heater life routinely exceeds 10 years. Silicon rubber has a high dielectric strength and is flame retardant and non-toxic.

Design versatility permits special heat profiles allowing zones of higher or lower

heat concentration as needed. Their flexible construction makes them very easy

to install on a variety of surfaces.

Silicon Rubber Heaters can be mounted to flat or curved surfaces. They are not

affected by vibration, flexing or repeated mechanical shock.

Silicon Rubber Heaters

Wire Wound (Standard)

- Standard leads- 10” Teflon

- Standard watt density– 5 watts/sq. in.

Available Options:

- Teflon leads with various lead lengths

- Silicon rubber leads with various lead lengths

- 6 ft. SJO cord set

- Pressure sensitive adhesive

- Stock thermostats

- 1 inch

- 2 inch

- 3 inch

- 4 inch

- 5 inch

- 6 inch

Width | Length | Watts | 120 Volt | 240 Volt |

|---|---|---|---|---|

1 | 3 | 15 | SRW010-030A | **** |

1 | 4 | 20 | SRW010-040A | **** |

1 | 5 | 25 | SRW010-050A | SRW010-050B |

1 | 10 | 50 | SRW010-100A | SRW010-100B |

1 | 15 | 75 | SRW010-150A | SRW010-150B |

1 | 20 | 100 | SRW010-200A | SRW010-200B |

1 | 25 | 125 | SRW010-250A | SRW010-250B |

1 | 30 | 150 | SRW010-300A | SRW010-300B |

1 | 35 | 175 | SRW010-350A | SRW010-350B |

1 | 40 | 200 | SRW010-400A | SRW010-400B |

1 | 80 | 400 | SRW010-800A | **** |

Width | Length | Watts | 120 Volt | 240 Volt |

|---|---|---|---|---|

2 | 2 | 20 | SRW020-020A | **** |

2 | 5 | 50 | SRW020-050A | SRW020-050B |

2 | 10 | 100 | SRW020-100A | SRW020-100B |

2 | 15 | 150 | SRW020-150A | SRW020-150B |

2 | 20 | 200 | SRW020-150A | SRW020-200B |

2 | 25 | 250 | SRW020-250A | **** |

2 | 30 | 300 | SRW020-300A | **** |

2 | 35 | 350 | SRW020-350A | **** |

2 | 40 | 400 | SRW020-400A | **** |

Width | Length | Watts | 120 Volt | 240 Volt |

|---|---|---|---|---|

3 | 3 | 45 | SRW030-030A | **** |

3 | 5 | 75 | SRW030-050A | SRW030-050B |

3 | 10 | 150 | SRW030-100A | SRW030-100B |

3 | 15 | 225 | SRW030-150A | SRW030-150B |

3 | 20 | 300 | SRW030-200A | SRW030-200B |

3 | 25 | 375 | SRW030-250A | **** |

3 | 30 | 450 | SRW030-300A | **** |

3 | 35 | 525 | SRW030-350A | **** |

3 | 40 | 600 | SRW030-400A | **** |

Width | Length | Watts | 120 Volt | 240 Volt |

|---|---|---|---|---|

4 | 4 | 80 | SRW040-040A | **** |

4 | 5 | 100 | SRW040-050A | SRW040-050B |

4 | 10 | 200 | SRW040-100A | SRW040-100B |

4 | 15 | 300 | SRW040-150A | SRW040-150B |

4 | 20 | 400 | SRW040-200A | SRW040-200B |

4 | 25 | 500 | SRW040-250A | **** |

4 | 30 | 600 | SRW040-300A | **** |

4 | 35 | 700 | SRW040-350A | **** |

4 | 40 | 800 | SRW040-350A | **** |

Width | Length | Watts | 120 Volt | 240 Volt |

|---|---|---|---|---|

5 | 5 | 125 | SRW050-050A | SRW050-050B |

5 | 10 | 250 | SRW050-100A | SRW050-100B |

5 | 15 | 375 | SRW050-150A | SRW050-150B |

5 | 20 | 500 | SRW050-200A | SRW050-200B |

5 | 25 | 625 | SRW050-250A | **** |

5 | 30 | 750 | SRW050-300A | **** |

5 | 35 | 875 | SRW050-350A | **** |

5 | 40 | 1000 | SRW050-400A | **** |

Width | Length | Watts | 120 Volt | 240 Volt |

|---|---|---|---|---|

6 | 5 | 150 | SRW060-050A | SRW060-050B |

6 | 10 | 300 | SRW060-100A | SRW060-100B |

6 | 15 | 450 | SRW060-150A | SRW060-150B |

6 | 20 | 600 | SRW060-200A | SRW060-200B |

6 | 25 | 750 | SRW060-250A | **** |

6 | 30 | 900 | SRW060-300A | **** |

6 | 35 | 1050 | SRW060-350A | **** |

6 | 40 | 1200 | SRW060-400A | **** |

Enclosure heaters

All come with 48” Teflon leads.

Width | Length | Volts | Watts | T-Stat Open | T-Stat Close | |

|---|---|---|---|---|---|---|

SRE020-050A | 2" | 5" | 120 | 25 | 55° F | 35° F |

SRE020-050B | 2" | 5" | 120 | 50 | 55° F | 35° F |

SRE020-060A | 2" | 6" | 120 | 60 | 110° F | 80° F |

SRE020-100A | 2" | 10" | 120 | 100 | 55° F | 35° F |

Silicon Rubber Heaters

Termination Options

- Hampton Controls Flexible Heaters come standard with 10” of 22 ga. Teflon leads. Other gauge leads available upon request.

- The leads are soldered at the lap connection then covered with a vulcanized lead cap.

- Lead Locations

- Standard lead option specifications

- Lead Termination Options

| Teflon | Silicon | SJO Cable | HPN Cable | HPN Cord Set |

|---|---|---|---|---|---|

A.W.G. | 22 GA. | 22 GA. | 18 GA. | 18 GA. Conductor | 18 GA. Conductor |

Voltage | 300 Volt | 300 Volt | 300 V/10 Amp. | 125 V/10 Amp. | 125 Volt/10 Amp. |

Temp. | 250°C/482°F | 150°C/302°F | 90°C/194°F | 90°C/194°F | 90°C/194°F |

O.D. | .060” | .060” | .285” | Flat | Flat |

| High Temperature, | Bonds well with silicon. | | | |

| Does not bond | Lower Temperature | Bulky lead cap. | Bulky lead | Bulky lead cap. |

- Insulated terminals or spade lugs

- Crimp connectors

- Standard electrical plugs

- Mini connectors

- Twist lock plugs

- Stripped ends

- Heat Shrink

- Silicone Sleeving

- S/S Braid

- S/S Conduit

- Lead caps can be placed anywhere on the heater. They can also be extended from the heater in order to allow for a more even heat distribution.

- Extended lead caps are often used to cure composites when tight temperature tolerances are needed.

- 1.5” x 1.5” cold section is required.

Silicon Rubber Heaters Terminations

- Hampton silicon rubber heaters are available with a variety of lead wires and terminations.

- Most can be applied to our in stock heaters.

- Teflon leads are our standard termination. 22 ga. Is standard, larger sizes are available. They're rated to 250 °C, and are abrasion resistant.

- Silicon rubber leads are rated to 150 °C and bond well to the silicone and are extremely moisture resistant. They are not very abrasion resistant.

- SJO cable is available in 2 or 3 conductor. It is rated to 90° C and is very durable. It does require a somewhat bulky lead cap.

- HPN cord is inexpensive and rated to 90°C

- Cordsets with molded plugs are available in HPN and SJO cord

- Spade Terminals and other special terminations are also available.

Silicon Rubber Heaters

Mounting Methods

There are several options for installation or mounting Silicon Rubber Heaters.

Pressure Sensitive Adhesive

An easy mounting method is to peel and stick. PSA is attached directly to one side of the

heater.

Just peel away the protective liner and attach the heater to the desired tool. PSA

is rated to a continuous temperature of 300 F and a maximum intermittent temperature

of 400 F. It is not recommended for curved surfaces. The heater should be installed

within 6 months of manufacture.

Factory Vulcanizing

Another method of installation is to send your tool to the Hampton Controls Heaters factory. The

tool is placed in a vacuum table and the SRH is vulcanized directly to the tool.

This is the

strongest bond available.

Field Applied Adhesive

SRH may also be attached with field applied adhesive. Hampton Controls Heaters will supply the required RTV to adhere the heater to

the desired surface.

We offer a room temperature curing adhesive. Apply a thin film of RTV on the entire bottom of the heater.

After positioning the heater on the part, use a roller to remove all air trapped between the heater and the part. The RTV should

be allowed to cure for 24 hours.

Pressure Sensitive Adhesive, also called PSA, is the simplest mounting method.

Just peel the protective paper from the back of the heater and stick it to your surface. PSA is rated to a continuous temperature of 300°F and intermittent usage up to 400°F.

PSA is only recommended for flat surfaces and should be used within 6 months of manufacture.

Field applied adhesive is more difficult to apply than PSA, but if done properly produces a superior bond.

Hampton Controls can supply a room temperature curing RTV rated to 400°F.

After applying a thin film between the heater and the surface, a roller should used to remove all air bubbles, then allowed to cure for 24 hours.

Boot Hooks and Lace

- Boot hooks and lace is the most common mechanical mount. Boot hooks are usually positioned 1.25” - 2” apart along the length of the heater.

- High temperature lace rated to 1000 F locks the heater in place similar to lacing a boot.

Spring and Grommets

- Each end of the spring is attached to a grommet, securing the heater to the tool.

- Grommets are spaced approximately 2” apart.

Snap Fasteners

- Snaps are only used on heaters with sponge insulation.

- Insulation is available in 1/16”, 1/8” 1/4”, 3/8” or 1/2” thickness

Rubber Rings

- High temperature rubber rings rated to 300° F.

- Can be used in conjunction with boot hooks and maintain constant tension through expansion and contraction

Velcro

- 1” wide Velcro straps secure the heater to the tool.

- Temperature rating: –30 °F - +380 °F

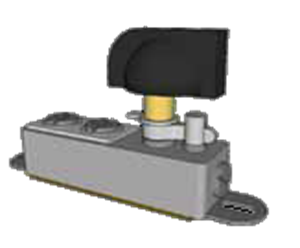

Temperature controls

Hampton Controls Silicon Rubber heaters can accommodate pre-set or adjustable thermostats, thermal cut-offs, and Type J thermocouples . The most common type of temperature controls are pre-set thermostats. Each has a specific temperature range and maximum amperage capability. Please contact the factory for availability.

- The most common type of temperature control are pre-set thermostats.

- They can be mounted to sense the temperature of the surrounding atmosphere or to sense the part temperature.

- 10 amps maximum at 240 volts. 14 amps maximum at 120 volts.

- Not recommended for low voltage applications

- Surface sensing

thermostats - Air sensing

thermostats - Adjustable

thermostats - THERMOCOUPLES

Surface sensing thermostats are mounted to monitor the temperature of the part that the heater is attached to. They can be mounted to stock heaters. Hampton Controls has several stock setting available and if other temperature setting are required, thermostats can be special ordered.

Close temperature | Open temperature |

|---|---|

32°F | 55°F |

80°F | 110°F |

145°F | 175°F |

170°F | 200°F |

270°F | 300°F |

Thermostats are snap action style and are rated to 10 amps at 240 volts or 14 amps at 120 volts. They are not recommended for low voltage heaters

Air sensing thermostats are mounted to sense the temperature of the ambient air. They are commonly used with enclosure heaters when the air temperature is more important than the heater temperature. Air sensing thermostats can be added to stock enclosure heaters and standard stock heaters. They are available in the same temperature ratings as the surface sensing thermostats..

Adjustable thermostats can only be used to sense part temperature. They are often used with drum heaters but can also be used with standard heaters. Temperature adjustment range is 25°F to 330°F.

Thermocouples can be mounted to any silicon rubber heater and any calibration (J, K, etc.) is available.

Thermocouples are small and are easily embedded anywhere on the heater. Almost any type of Thermocouple can be used. Type J is the most common.

Stock Thermostats

- Pre-set: on at 35°F / off at 55 F

- Pre-set: on at 80°F / off at 110 F

- Pre-set: on at 145°F / off at 175 F

- Pre-set: on at 170°F / off at 200 F

- Pre-set: on at 270°F / off at 300 F

- Adjustable 25°F to 330 F

*Consult factory for other calibrations

- Drum Heaters

- Optional Thermostats

- Stock List

Hampton's drum Heaters are an easy way to heat up drum contents. Various sizes and lengths allow you to heat up practically any drum, pail or barrel. Uniform heat prevents scorching or degradation of the contents. The silicon rubber band heater is placed below the level of the fluid. The easy spring lock-up provides movement of the band when content levels fluctuate. The band style drum heater can be used on plastic, alloy or just about any material.

Applications:

- Freeze protection

- Viscosity control

- Speeding up the flow of liquids

- Maintaining product consistency

Features:

- Easy installation with spring loaded fastener.

- 3 conductor cord set.

- Internally grounded.

- Can be wrapped around any object

- Options thermocouples, RTD’s, holes and cutouts

Thermostats can easily be attached to stock drum heaters. Available stock thermostats include:

- Adjustable 25°F - 330°F

- Pre-set (see above stock thermostat table)

Stock Drum Heater Specifications*

All heaters come with 6 ft. SJO cord set and easy spring loaded fastener.

| Capacity | Width | Height | Volts | Watts |

|---|---|---|---|---|---|

SRD5-31-N | 5 Gallon Drum | 3 | 31 | 120 | 300 |

SRD5-41-N | 5 Gallon Drum | 4 | 31 | 120 | 550 |

SRD55-31-N | 55 Gallon Drum | 3 | 64 | 120 | 1000 |

SRD55-32-N | 55 Gallon Drum | 3 | 64 | 240 | 1000 |

SRD55-41-N | 55 Gallon Drum | 4 | 64 | 120 | 1500 |

* 5 gallon fits 11.5” diameter drum. 55 gallon fits 22.5” diameter drum

Order Your Silicon Rubber Heaters

Hampton Controls looks forward to serving you and supplying you with your Industrial Needs.

Feel free to call us if you need any assistance at: 724-861-0150

See our Large Supply by Clicking on the Stock List Tab above or Configure your Silicon Rubber Heaters here.

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.