- Overview

- Description

- Termination

Options - Custom Design

Docs & Specs

Cast In Heaters by Hampton Controls

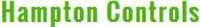

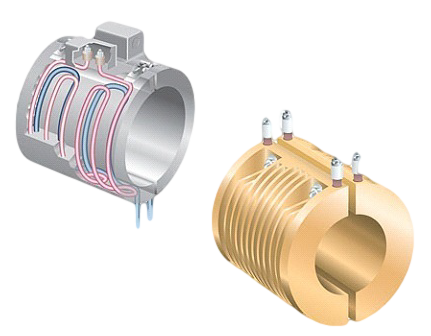

Cast-in liquid cooled barrel heaters are the most common cast -in heater design used on plastics extrusion barrels.

Liquid Cooled and Air Cooled Cast In Barrel Heaters

The liquid cooling tubes run symmetrical to the heater element, which provides a uniform cooling pattern across the body of the casting. This cooling function dissipates heat rapidly from the cast-in barrel.

To maintain lower watt densities important for good heater life, the largest possible diameter steel sheath tubular heater is used. Cooling tube extensions can be cut to your specified length.

Many options available:

- Liquid or Air Cooled

- Aluminum, Bronze, Brass

- And other custom types

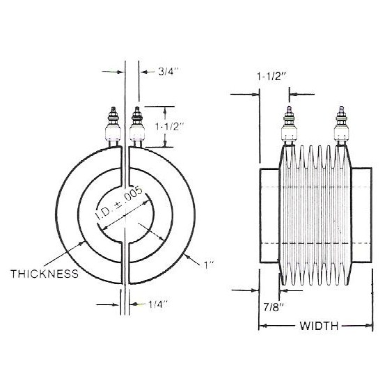

Air Cooled Finned Cast In Barrel Heaters

Air Cooled finned Barrel Heater designs provide effective heating and cooling for plastics extrusion barrels as well. For smaller extruders or applications requiring rapid cooling, this design can be manufactured to a low profile thickness. The standard height of 1" is common with Air Cooled Finned Barrel Heaters.

This pattern is designed to allow the optimal airflow around the casting for maximum cooling rates. Typically the forced air for the cooling function is driven by a shroud and blower system that is an integral part of the extruder, however these cast- in heaters can be utilized with an individual shroud and blower assembly for increased cooling control of the individual heater zones.

Typical Cast In Heaters Design from Hampton Controls

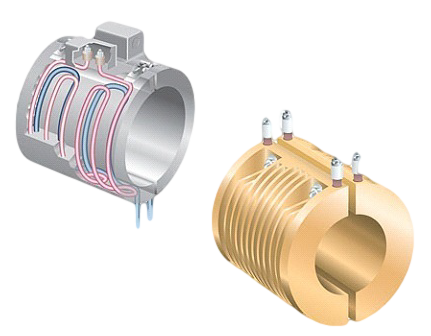

Cylindrical Heat and Cool Heaters

Cylindrical Heat and Cool Heaters for Extrusion Machinery

These cast barrel heaters are available with a wide range of standard and custom options for maximizing machine operations using various material types.

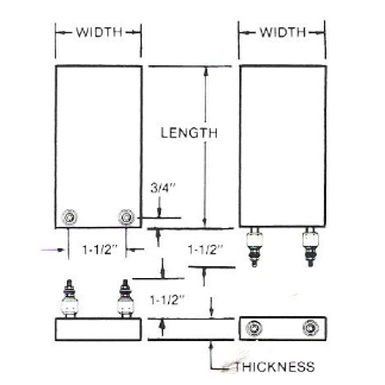

Platen Heaters

Hampton Controls Platen Heaters are a versatile cast-in design that can be adapted to a myriad of applications like:

- Packaging Equipment

- Food Service Equipment Warming

- Die Heaters

- Heat Transfer Presses

- and more.

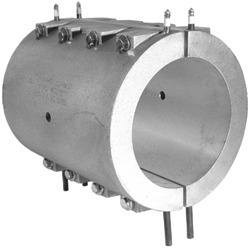

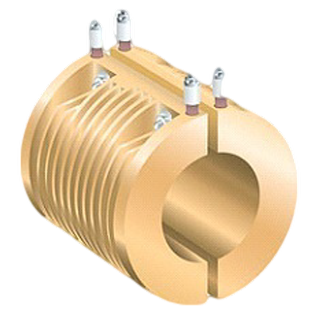

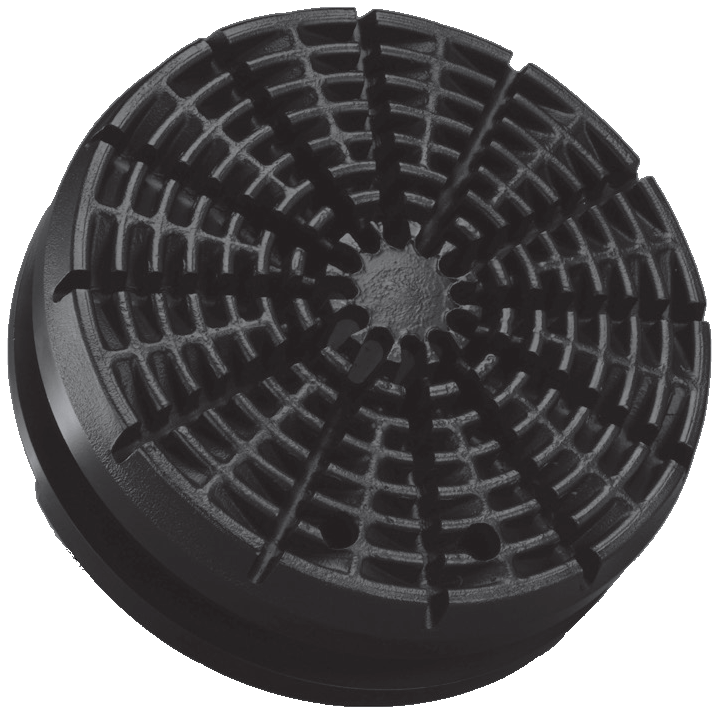

Cylindrical Finned Heaters

Great for Air-Cool Extrusion Machinery, these Cylindrical Finned Heaters are available at Hampton Controls.

Finned air-cooled cast-in barrel heater designs provide effective heating and cooling for plastics extrusion barrels. The fin pattern can be supplied as a standard height of 1” or manufactured to a low profile thickness for small extruders or applications requiring rapid cooling.

Glue Potts and Pan Heaters

These are great for Industrial and Food Warming Applications.

Small Diameter Cylindrical Heaters

These are often used for applications like:

- Pipes

- Dies

- Nozzle Heating

Special or Custom Cast In Heaters Designs

Hampton Controls can design what you need per your exact specification for whatever your heating requirements. Our engineering staff and help you with your custom designs.

Other sheath materials are also available for application considerations. Commonly specified are 316 stainless steel, sopper clad steel for metal casting, Inconel for high temperature applications, and titanium for severely corrosive solution heating.

Contact Hampton Controls for a quote today.

- Electrical

Terminations - Cooling

Terminations - Protective

Housings

Many Variations of Electrical Terminations for Hampton Controls Cast-In Heaters

Electrical Terminations for Cast-In Heaters

Type S

Ceramic Insulated

10-32 Screw Terminal

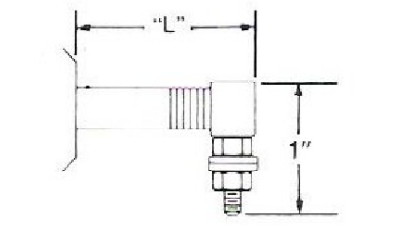

Electrical Terminations for Cast-In Heaters

Type A

Right Angle

10-32 Screw Terminal

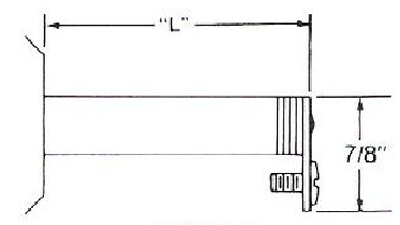

Electrical Terminations for Cast-In Heaters

Type R

Screw Lug Terminal

8-32 Screw

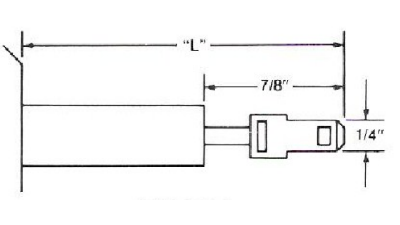

Electrical Terminations for Cast-In Heaters

Type D

Quick-Disconnect Spade

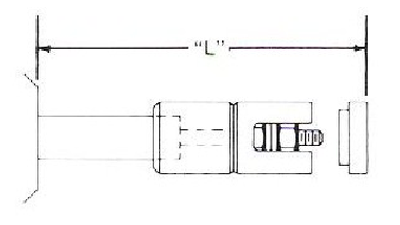

Electrical Terminations for Cast-In Heaters

Type T

Ceramic Insulated

For Type S

Electrical Terminations for Cast-In Heaters

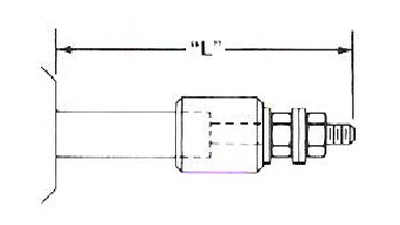

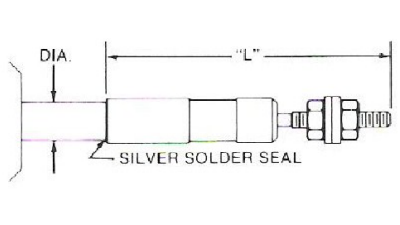

Type HS

Hermetic Seal Screw Terminal

Lenght | Diameter | Thread |

|---|---|---|

1-1/8 | .430 | 1/4-28 |

1-3/8 | .315 | 10-32 |

1-5/8 | .250 | 8-32 |

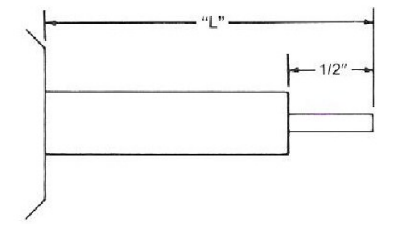

Electrical Terminations for Cast-In Heaters

Type P

Plain Terminal Pin

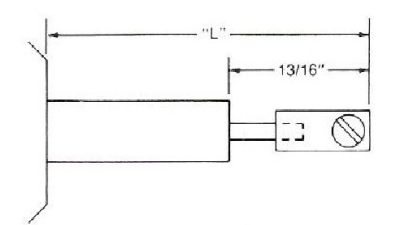

Electrical Terminations for Cast-In Heaters

Type L

Terminal Lug

10-32 Screw

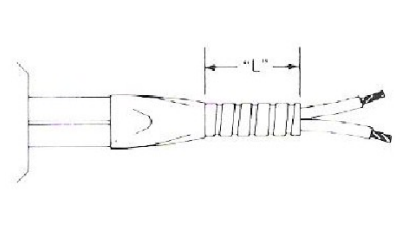

Electrical Terminations for Cast-In Heaters

Type C

Flexible Cable Leads

The Variations of Cooling Tube Terminations for Hampton Controls Cast-In Heaters

Cooling Tube Terminations for Cast-In Heaters

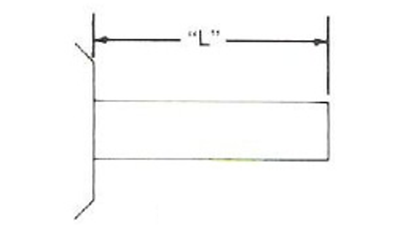

Type C1

Plain Tube Termination

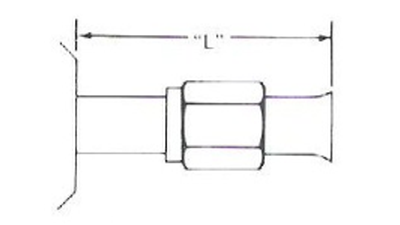

Cooling Tube Terminations for Cast-In Heaters

Type C2

37 Degree Flare Nut Fitting

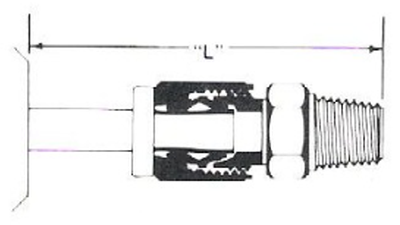

Cooling Tube Terminations for Cast-In Heaters

Type C3

Compression Fitting

3/8 Diameter #55-0010

1/2 Diameter #55-0011

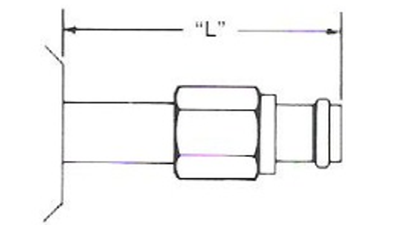

Cooling Tube Terminations for Cast-In Heaters

Type C4

Brazed Seal

Cooling Tube Terminations for Cast-In Heaters

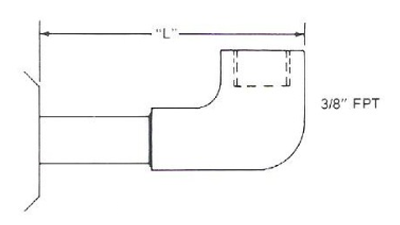

Type C5

Brazed Angle Fitting

Cooling Tube Terminations for Cast-In Heaters

Type C6

Cast-In Fitting

3/8" FPT

Protective Housings for Hampton Controls Cast-In Heaters

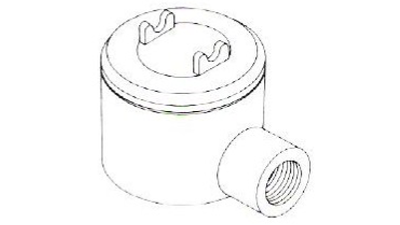

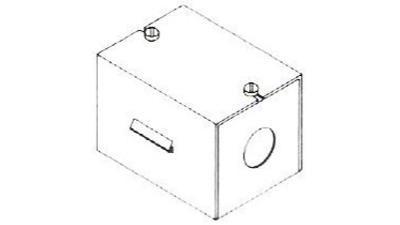

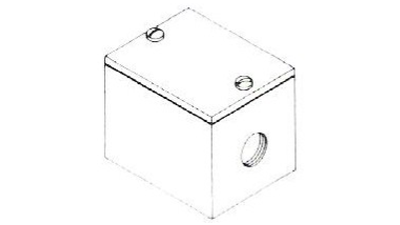

Explosion Proof Box

Sheet Metal Box

Cast-In Box

See our Cast In Heaters Specifications

Custom Cast In Heaters Designed

per Exact Specifications for your Heating Requirements

Cast Materials | Max. Operating | |

|---|---|---|

Aluminum | 750 °F | (400 °C) |

Bronze | 1100 °F | (595 °C) |

Iron | 900 °F | (482 °C) |

Cast Processes | |

|---|---|

| |

Electrical | | | |||

|---|---|---|---|---|---|

Voltages: | | | |||

Element diameter | .260 .315 .430 | | | ||

Maximum Volts | 240 277 600 | | | ||

(Three phase available on large heaters) Maximum watt densities depends on size and application. Consult Factory ! | | | |||

[thrive_text_block color=”light” headline=”Machine Finish”]

- A finish of 125 RMS can be provided on any flat and I.D. surfaces when required.

- Platen surfaces can be belt sanded to within .005″ or milled to .001′ flat.[/thrive_text_block]

[thrive_text_block color=”light” headline=”Holes, Cutouts, Thermowells”] Mounting or clearances holes, cutouts, and thermowells for inserting temperature measurement probes can be cast-in or machined per your specifications.[/thrive_text_block]

[thrive_text_block color=”light” headline=”Testing”]

- Electrical per U.L. 1030

- Dimensional per specifications

- Pressure test of cooling tubes when applicable

- Radiographs when requested or specified[/thrive_text_block]

[thrive_text_block color=”light” headline=”Inserts”]Threaded studs, precision components parts, bushings, and special design parts can be accurately cast in place.[/thrive_text_block]

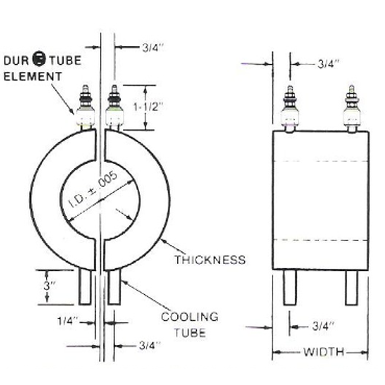

STANDARD REFERENCE DIMENSIONS | |||||||

|---|---|---|---|---|---|---|---|

Type | Heat Diameter | Cooling Tube Diameter | Standard Thickness | I.D. | Width | Length | Maximun Volts |

Semi-cyl | .260 | - | .62 | 1"-3" | 1"3" | - | 240 |

Semi-cyl | .315 | - | .75 | 3"-6" | 2.5"24" | - | 277 |

Semi-cyl | .430 | - | 1.00 | 3"-24" | 3"-24" | - | 550 |

Semi-cyl | .430 | .375 | 1.38 | 3"-24" | 3"-24" | - | 550 |

Semi-cyl | .430 | .500 | 1.75 | 3"-24" | 3.5"-24" | - | 550 |

Semi-cyl | - | .500 | 1.00 | 3"-24" | 3.5"-24" | - | - |

Flat | .260 | - | .62 | - | 1.5"-24" | 36" max | 250 |

Flat | .315 | - | .75 | - | 2"-24" | 36" max | 277 |

Flat | .430 | - | 1.00 | - | 2.5"-24" | 36" max | 550 |

For casting designs with dimensions beyond standard limits, contact Hampton Controls, Inc.

Cylindrical Heat & Cool

Cylindrical Heat with Fins

Flat Platen Heater

Ordering Notes

- Cast design.

- Supply a complete drawing showing all dimensions and critical tolerances.

(Refer to reference dimensions and specifications above.) - Heater element and cooling tube (if required) exit locations.

- Electrical terminations and housings, type S is standard.

- Wattage and voltage rating

- Quantity

Hampton Controls is ready to Help You Configure your Custom Cast-In Heaters today.

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.